Product information

Reviews

Shipping & returns

Product information

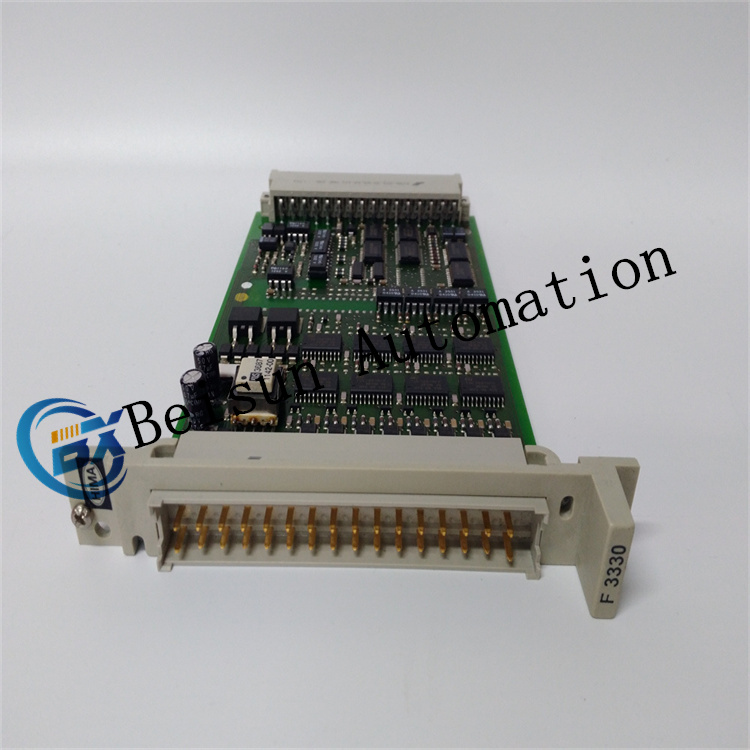

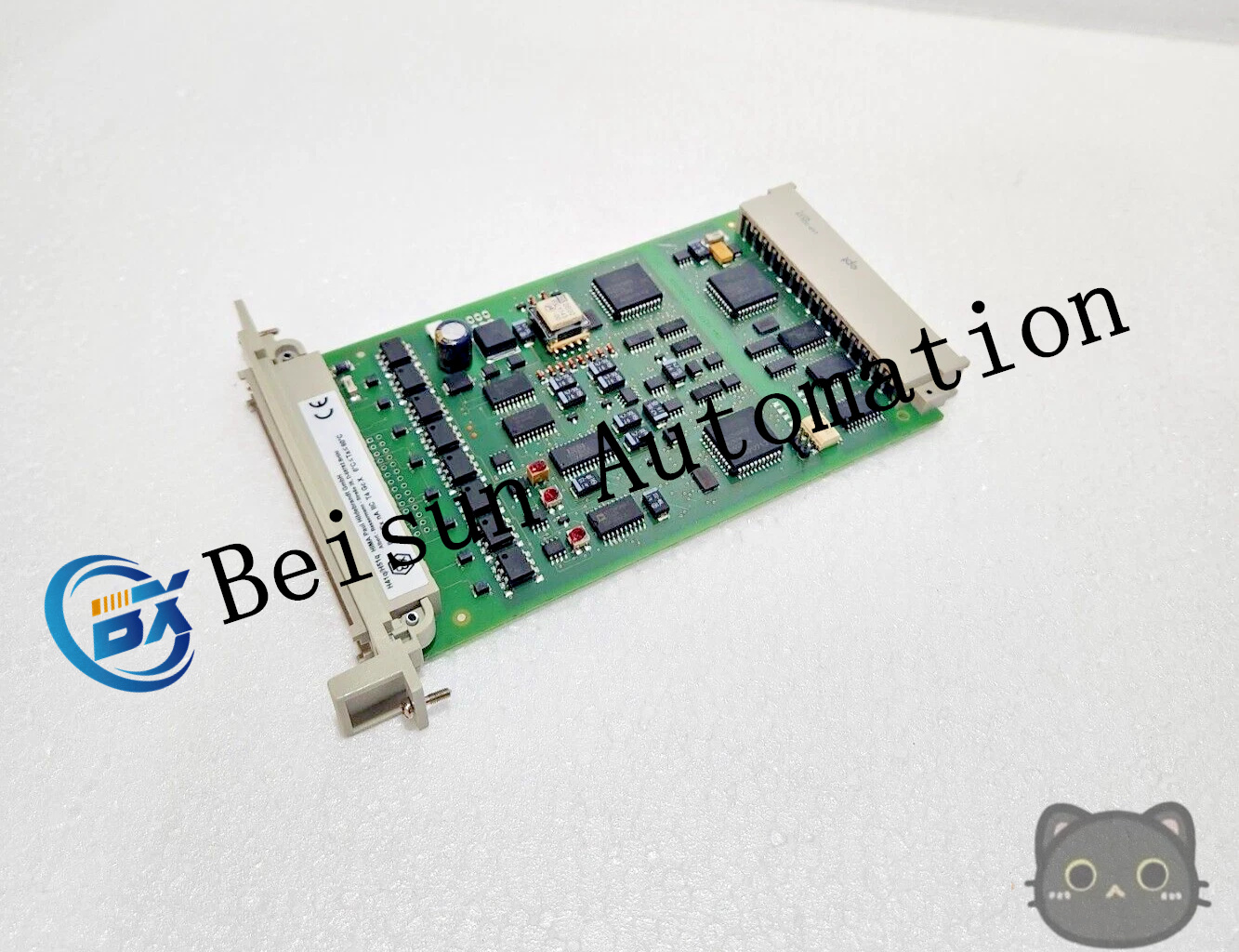

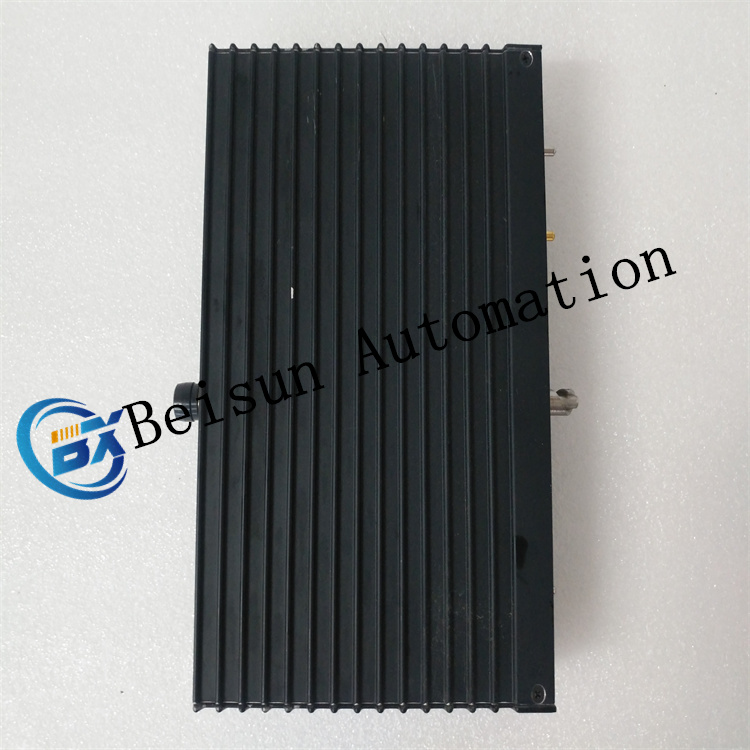

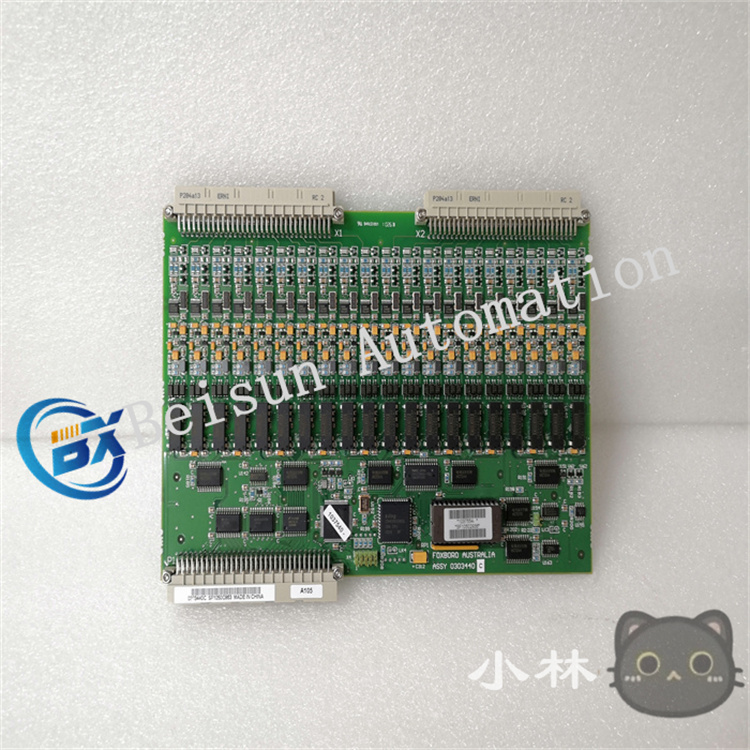

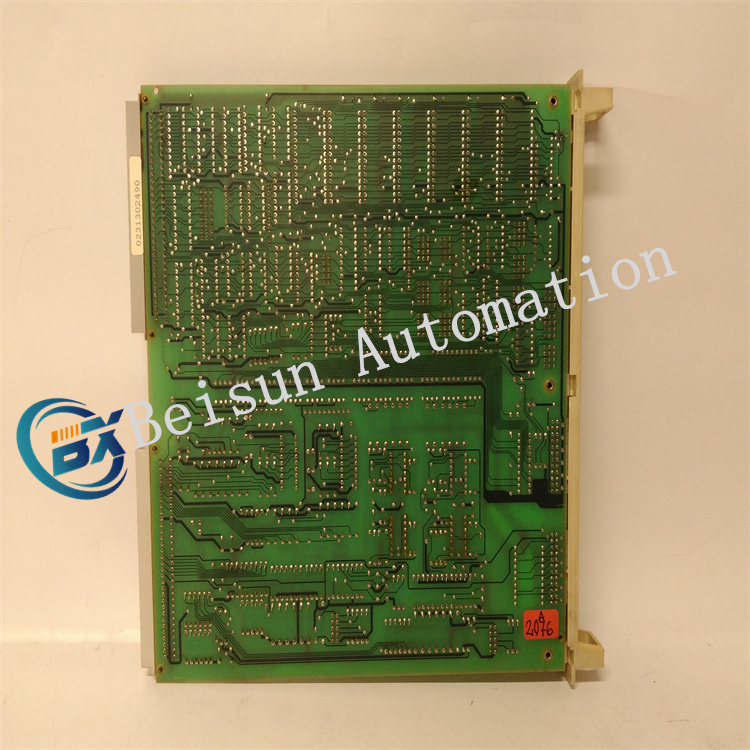

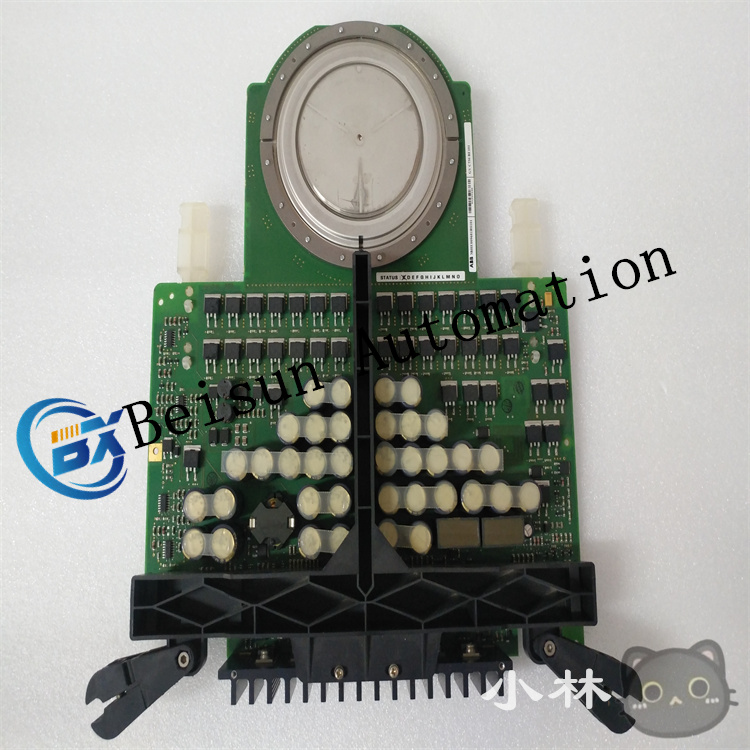

HIMA F3318 automation control module

Functional characteristics

High reliability: Advanced fault tolerance technology and redundant design, with self-diagnosis and fault detection functions, can operate stably in harsh industrial environments, to ensure continuous and reliable operation of the system. For example, it may have dual redundant power modules and communication channels, so that when one fails, the other can immediately take over and avoid system outages.

Security performance: Usually meets high security integrity level standards, such as SIL3. This makes it suitable for industrial scenarios with high safety requirements, such as chemical, oil, natural gas and other industries, which can effectively prevent safety accidents caused by system failures and ensure the safety of personnel and equipment.

Flexible configuration: Supports a variety of configuration methods, and can be customized according to different industrial control requirements. Users can easily adjust the functions and parameters of the module through programming software to adapt to a variety of complex control tasks, whether it is simple logic control or complex process control, accurate control can be achieved through reasonable configuration.

Application field

Petrochemical: In the process of petroleum refining and chemical production, it is used for the status monitoring and control of various reactors, storage tanks, transportation pipelines and other equipment. For example, real-time monitoring of the temperature, pressure, liquid level and other parameters in the reactor, according to the preset process requirements to control the opening and closing of the feed and discharge valves, as well as the start and stop and speed of the agitator, to ensure the safety and stability of the production process, to prevent leakage, explosion and other safety accidents.

Power: In power plants, substations and other power systems, used for the monitoring and protection of generators, transformers, switchgear, etc. For example, monitoring the operating parameters of the generator, such as voltage, current, frequency, etc., to achieve automatic regulation and protection of the generator; Carry out remote control and status monitoring of the high-voltage switch in the substation, find and deal with equipment faults in time, ensure the reliable operation of the power system and improve the quality of power supply.

Pharmaceutical: In the pharmaceutical production workshop, for the control of drug production equipment and the environment. For example, monitoring environmental parameters such as temperature, humidity and cleanliness during drug production to ensure that the production environment meets drug quality requirements; Precise control of drug filling, packaging and other equipment to ensure accurate dosage and packaging quality of drugs, to meet the strict production specifications and quality standards of the pharmaceutical industry.

Reviews

There are no reviews yet.