Product information

Reviews

Shipping & returns

Product information

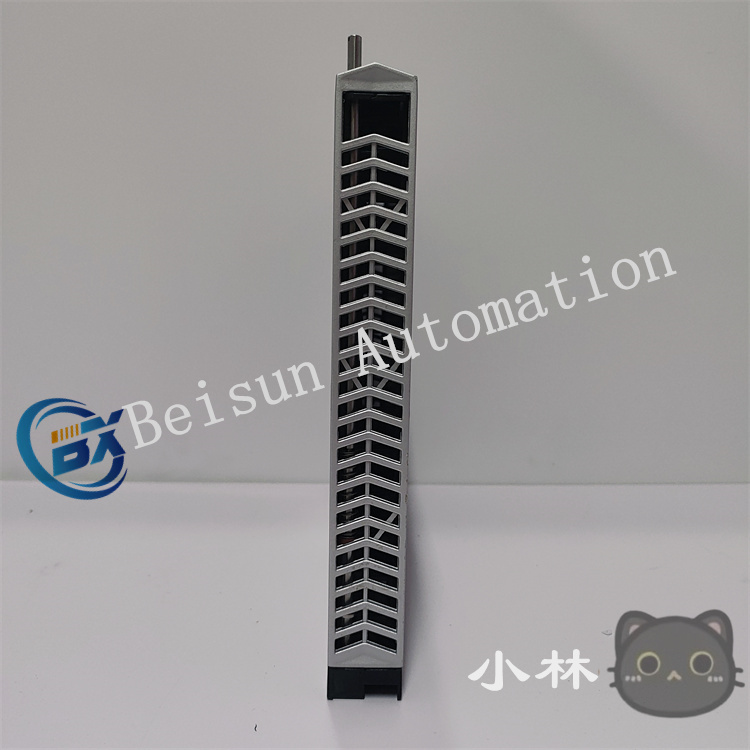

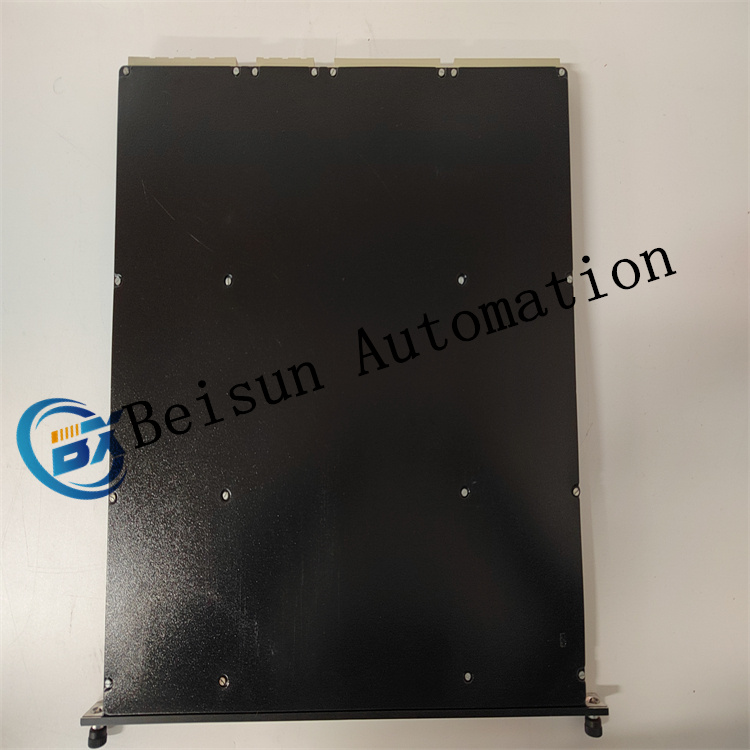

Emerson 5X00031H01 input/output module

Technical parameters

Input signal range: Analog input typically supports multiple standard signal ranges, such as 4-20mA, 0-10V, etc. Digital input generally supports standard-level signals such as TTL and CMOS.

Output signal range: Analog output also supports common signal ranges, such as 4-20mA, 0-10V, etc., to drive various analog-controlled devices. Digital output can provide sufficient driving capacity to control digital actuating elements such as relays and contactors.

Accuracy: The accuracy of analog input and output can typically reach ±0.1% to ±0.5% FS (full scale), and the specific accuracy index depends on the specific model and configuration of the module.

Response time: The response time of the module is relatively short, capable of quickly responding to the input signal and outputting the processed signal to the field device. Generally, the response time is in the millisecond range.

Power supply requirements: Usually, a stable DC power supply, such as 24V DC, needs to be provided to ensure the normal operation of the module. The power supply ripple requirement is generally within a certain range to ensure the stability of the module.

Application field

Process control system: In the process control systems of industries such as chemical engineering, petroleum, and pharmaceuticals, it is used to connect various sensors and actuators to achieve monitoring and control of process parameters such as temperature, pressure, flow rate, and liquid level.

Power system: In power systems such as power plants and substations, it can be used to collect electrical parameters such as voltage, current, and power, and output control signals to switchgear, relay protection devices, etc., to achieve stable operation and protection of the power system.

Industrial automated production lines: In industrial automated production lines such as automotive manufacturing and electronic equipment manufacturing, they are used to connect various automated equipment, such as robots, conveyor belts, CNC machine tools, etc., to achieve automated control and coordinated operation of the production line.

Reviews

There are no reviews yet.