Product information

Reviews

Shipping & returns

Product information

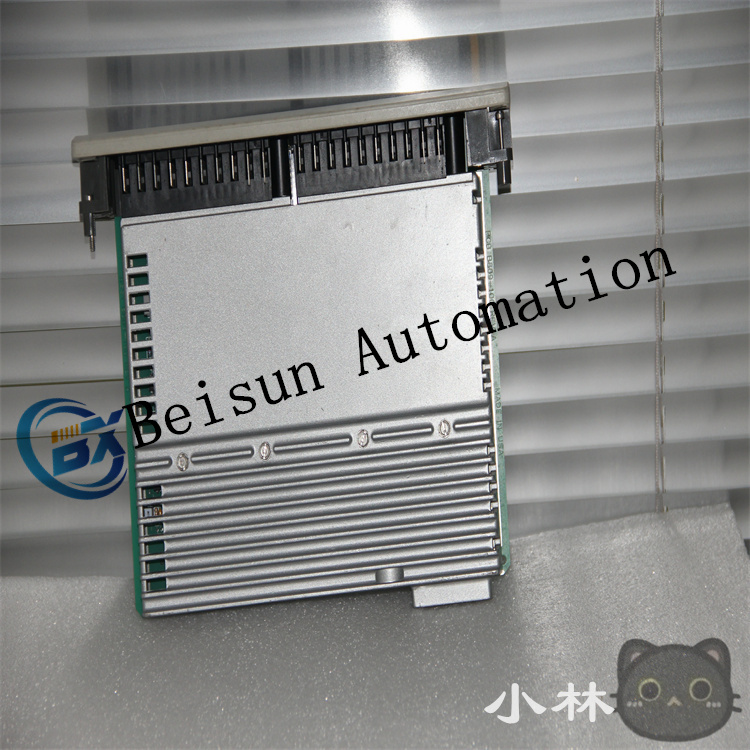

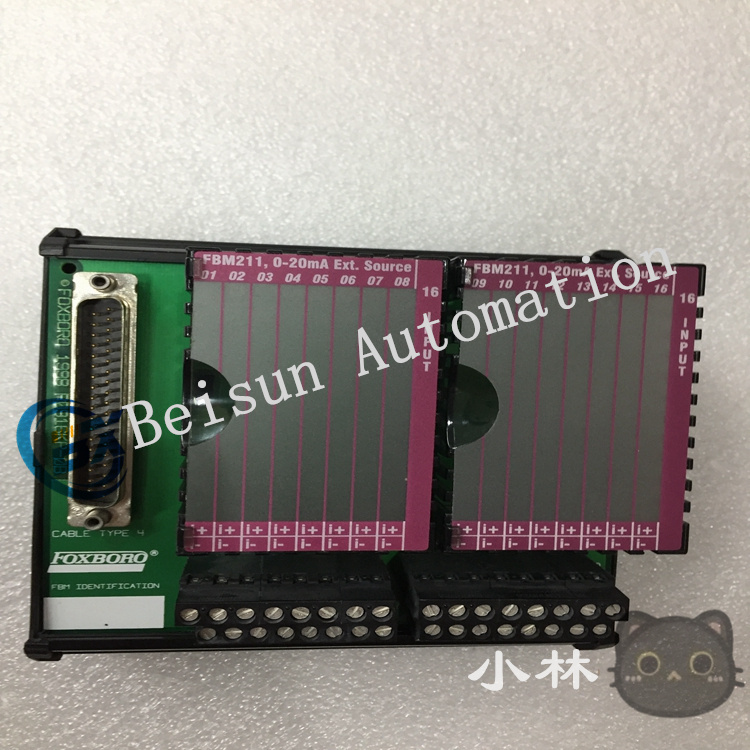

Foxboro FBM201C I/O subsystem interface module

High-precision signal acquisition: By adopting sigma-delta data conversion technology, the analog accuracy (including linearity) can reach ±0.03% of the measurement range, with a precision temperature coefficient of ±50ppm/º C. It can achieve high-precision analog signal acquisition in different temperature environments and accurately capture the minute changes in sensor signals.

High-speed data processing: It can provide a new analog input reading every 25 milliseconds, featuring a fast data acquisition and processing speed. It can promptly respond to the dynamic changes in industrial sites and meet the requirements of control systems with high real-time demands.

Flexible configuration options: The integration period can be configured, and the integration time can be adjusted according to the actual situation on site, effectively eliminating process noise and power line frequency noise. At the same time, parameters such as the change rate limit can also be configured to optimize the signal acquisition and processing effect, adapting to different industrial application scenarios.

High-reliability design: It features 8 isolated independent channels, each of which is electrically isolated from other channels and grounding, enhancing the module’s anti-interference capability in complex electromagnetic environments and ensuring the accuracy and stability of signal transmission. In addition, communication with the relevant FCM or FCP through the redundant 2Mbps module fieldbus ensures the reliability of data transmission, enabling stable operation even in harsh industrial environments.

Wide operating temperature range: The operating temperature range is -40 to 70°C, capable of adapting to various harsh industrial environments. Whether in high-temperature industrial furnaces or low-temperature outdoor locations, it can maintain stable performance, providing a guarantee for the continuity of industrial production.

Calibration-free design: No calibration modules or terminal components are required. This not only reduces maintenance workload and costs but also lowers downtime caused by calibration, enhancing the efficiency and economy of industrial production.

.jpg)

Reviews

There are no reviews yet.