Product information

Reviews

Shipping & returns

Product information

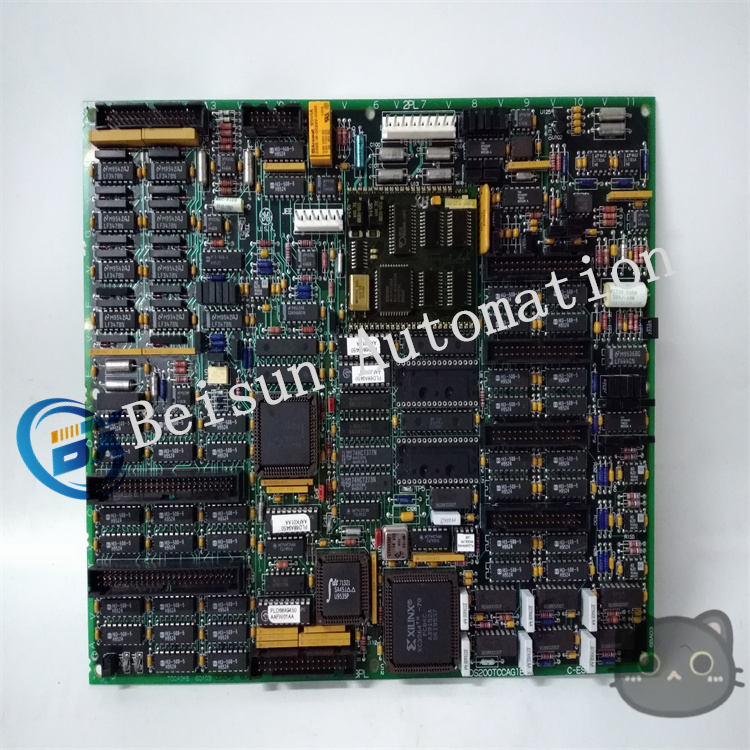

GE IS420UCSBH4A Controller Module

Application Scenarios

Gas Turbine Control Systems: This module is specifically designed for gas turbine control systems, belonging to the Mark VIe series. It can be used in gas turbine control systems equipped with a 1066 MHz Intel EP80579 microprocessor, and is commonly found in applications such as EX2100e and LS2100e.

Gas Turbine Control Systems: This module is specifically designed for gas turbine control systems, belonging to the Mark VIe series. It can be used in gas turbine control systems equipped with a 1066 MHz Intel EP80579 microprocessor, and is commonly found in applications such as EX2100e and LS2100e.

Functional Features

Industrial-Grade Rugged Design: It features anti-vibration, anti-electromagnetic interference, and durability, enabling stable operation in various harsh industrial environments and ensuring reliable system performance.

Industrial-Grade Rugged Design: It features anti-vibration, anti-electromagnetic interference, and durability, enabling stable operation in various harsh industrial environments and ensuring reliable system performance.

Rich I/O Channels: It supports multiple input/output interfaces, including two Hall effect pulse inputs for precise speed measurement, two analog inputs for analog signal acquisition, and four digital input/output interfaces, which can meet a variety of control needs.

Powerful Communication Capability: Through the onboard IONet interface, it can easily communicate with I/O packs to achieve fast data transmission and exchange. It also supports multiple communication protocols, facilitating integration with different devices and systems. Additionally, it can connect with other devices via Ethernet or serial communication interfaces to realize remote monitoring.

Efficient Data Processing Capability: Equipped with a 1066 MHz Intel EP80579 microprocessor and paired with the QNX Neutrino real-time multitasking operating system, it can quickly execute complex control algorithms and data processing tasks, and respond to various control commands in an extremely short time.

Flexible Expandability: As part of the Mark VIe series, it can seamlessly integrate with other Mark VIe controllers and I/O modules, allowing users to expand and customize the system according to actual needs.

Fault Diagnosis and Safety Functions: It has advanced fault diagnosis and self-protection functions, which can detect potential problems or abnormal situations. In case of abnormalities, it can quickly cut off the fault source to protect system safety. It also supports functional safety loops to achieve SIL 1 and 0 functions, meeting the requirements of industrial applications with high safety performance demands.

Easy Maintenance and Debugging: It has a self-diagnostic function that can detect and report faults, making it convenient for users to discover and solve problems in a timely manner, reducing maintenance costs. Moreover, it is easy to debug, facilitating users in program debugging and system testing.

Working Principle

The IS420UCSBH4A controller module, based on its hardware architecture and supported by the QNX Neutrino operating system, communicates with I/O packs through the IONet interface, acquires input data, executes control algorithms, and outputs control signals to realize the control of gas turbines. The specific working principle is as follows:

The IS420UCSBH4A controller module, based on its hardware architecture and supported by the QNX Neutrino operating system, communicates with I/O packs through the IONet interface, acquires input data, executes control algorithms, and outputs control signals to realize the control of gas turbines. The specific working principle is as follows:

Data Acquisition and Input: The module is equipped with multiple input channels and can be connected to various sensors on the gas turbine, such as temperature sensors, pressure sensors, and speed sensors. These sensors convert physical quantities such as temperature, pressure, and speed during the operation of the gas turbine into electrical signals, which are input into the controller module. Through the onboard IONet interface, the controller can access all I/O networks and obtain these input data, providing a basis for subsequent calculations and control.

Data Processing and Calculation: The IS420UCSBH4A is equipped with a 1066 MHz Intel EP80579 microprocessor. Supported by the QNX Neutrino real-time multitasking operating system, it can quickly process the collected data. The controller analyzes and calculates the input data according to preset control algorithms and programs, such as calculating the deviation between the actual operating parameters of the gas turbine and the set values, and judging whether the equipment operating status is normal. The module uses control block language and boolean logic in the form of relay ladder diagrams, supporting 16-bit and 32-bit signed and unsigned integers, as well as 32-bit and 64-bit floating-point number programming, which can realize complex logical operations and control strategies.

Control Signal Output: Based on the results of data processing and calculation, the controller module sends out corresponding control signals through the output channels. These signals can be used to control components such as the fuel supply system, ignition system, and valve opening of the gas turbine. For example, when it is detected that the speed of the gas turbine is lower than the set value, the controller will output a signal to increase the fuel supply to raise the speed; if a certain part is found to have an excessively high temperature, it will send a signal to control the cooling system to increase the cooling intensity.

Communication and Interaction: The module communicates with other devices or systems through the IONet interface, and can send the operating data of the gas turbine to the upper computer or other monitoring devices, facilitating operators to monitor the equipment status in real-time. It can also receive commands from the upper computer, such as modifying control parameters, starting or stopping the equipment, etc. Meanwhile, using the IEEE 1588 protocol can synchronize the clocks of I/O packs and controllers within 100 microseconds, ensuring the accuracy and timeliness of data interaction.

Fault Detection and Protection: The module has a fault detection function and continuously monitors the status of itself and the gas turbine during operation. When abnormal situations are detected, such as sensor failures or parameters exceeding the normal range, it will promptly issue an alarm signal. At the same time, it can take corresponding measures according to the preset protection strategy, such as cutting off the power supply of some key components to prevent the expansion of faults and protect the safety of gas turbine equipment.

Realization of Safety Functions: Functional safety loops can be realized by using Mark VIeS UCSBSIA safety controllers and safety I/O modules to achieve SIL 1 and 0 functions. These special control hardware and software have IEC 61508 certification, which can ensure that the system can reliably perform safety-related operations in dangerous situations under the premise of meeting safety standards.

Reviews

Be the first to review “GE IS420UCSBH4A Controller Module” Cancel reply

Shipping & returns

Free and fast shipping

Cras condimentum sapien eu congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Easy returns

Aliquam dapibus placerat dui, ac ullamcorper odio dapibus eget. Sed aliquam leo pellentesque est blandit, sit amet posuere dui maximus.

Order tracking

Nullam lacinia iaculis erat ut fermentum. Praesent volutpat sagittis dictum. Mauris quis egestas dui, eu iaculis turpis.

24/7 customer support

Congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Reviews

There are no reviews yet.