Product information

Reviews

Shipping & returns

Product information

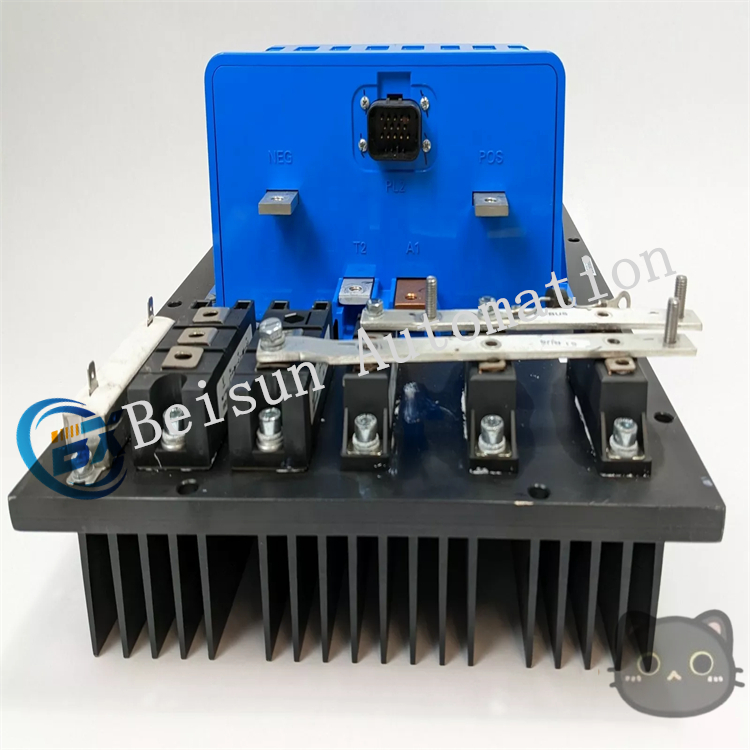

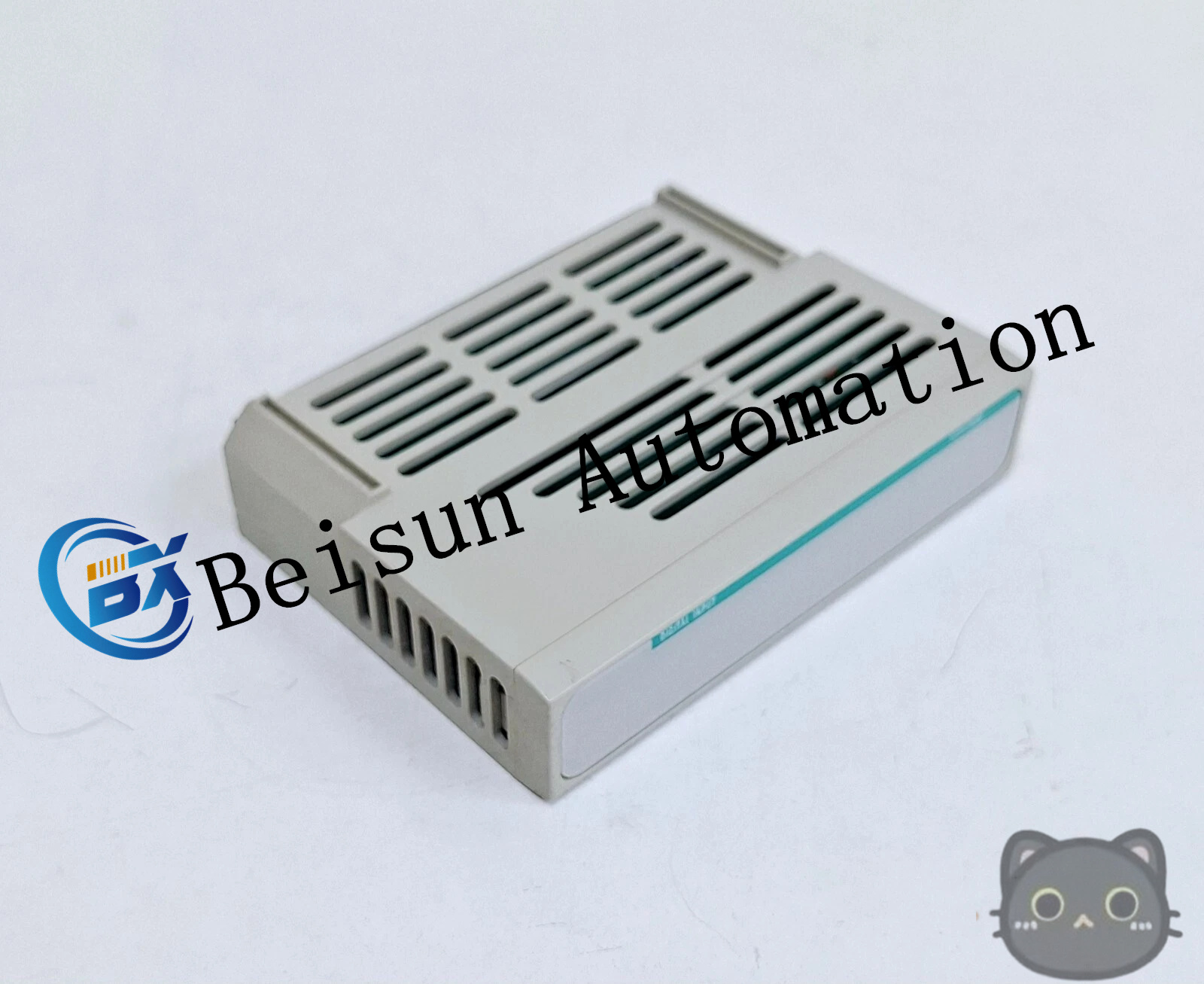

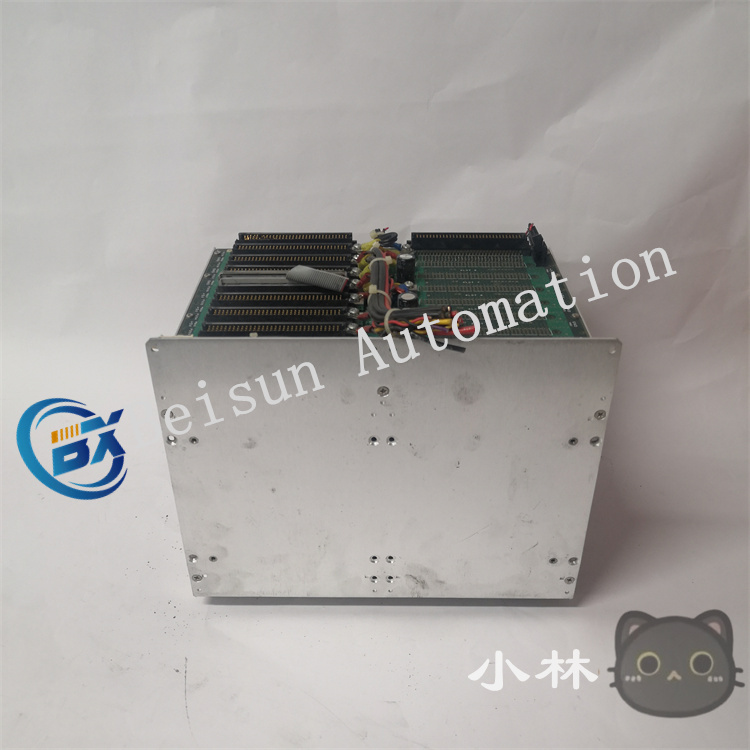

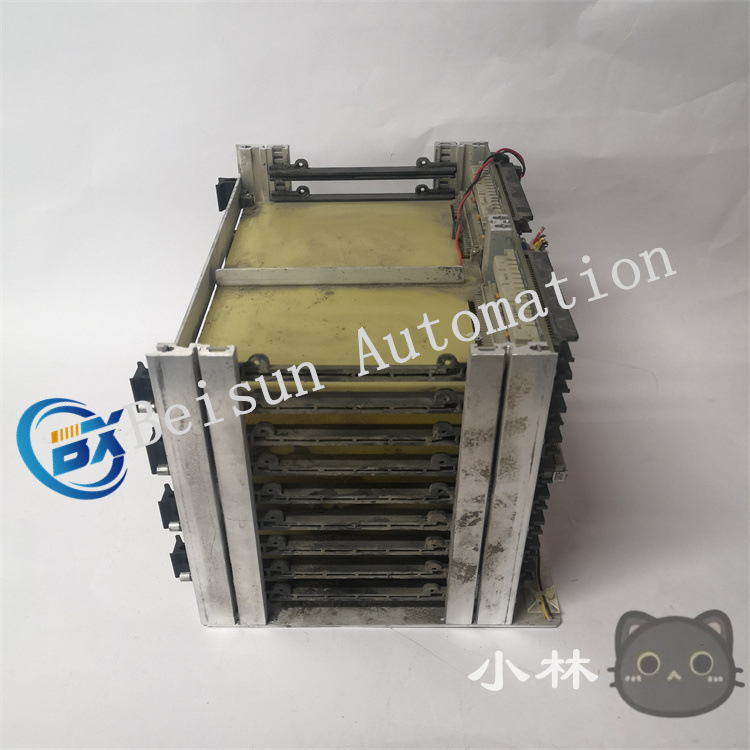

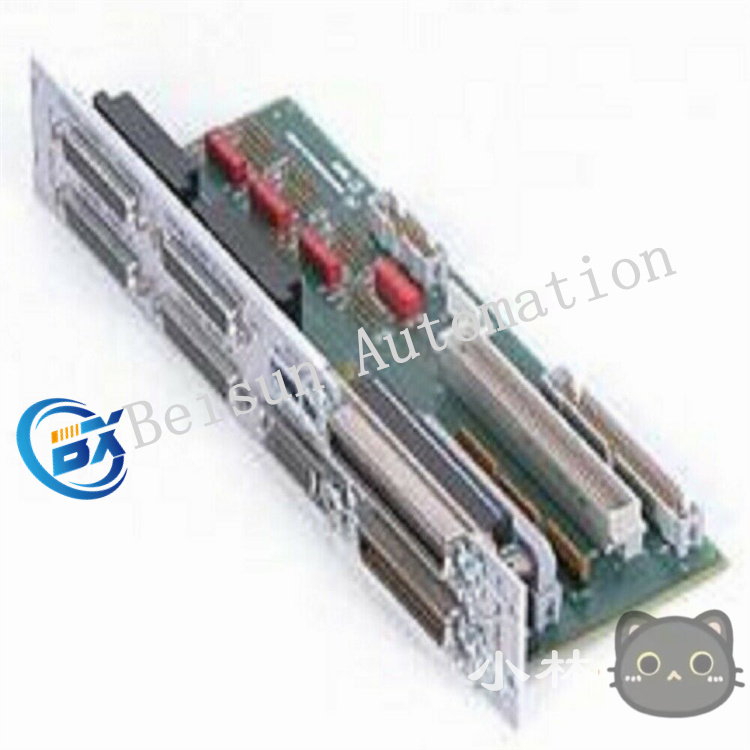

GE 151X1207BB55SA01 VersaMax Series Industrial Control Module

Module Functions:

- Powerful Control Capability: The VersaMax modular CPU offers many functions typically found only in large PLCs, including up to 128KB of memory for applications, floating-point arithmetic, real-time clock, subroutines, and PID control. It is that the 151X1207BB55SA01 also has similar functions and can handle complex control tasks.

- Rich I/O Interfaces: The VersaMax series provides a wide range of discrete, analog, mixed, and special I/O modules. These modules can be freely combined to form a single-rack I/O system with up to 256 I/O points and an extended I/O system with up to 2048 I/O points. Therefore, this module may also have various types of input and output channels, which can be connected to various sensors and actuators to achieve precise monitoring and control of industrial processes.

- Network Communication Function: This series supports multiple communication protocols such as Genius, DeviceNet, Modbus/TCP, Profinet, Profibus DP, etc., and usually has RS-232, RS-485 serial ports, and Ethernet interfaces. It is inferred that the 151X1207BB55SA01 may also have these communication capabilities, facilitating data interaction with other devices or systems and realizing functions such as remote monitoring and control.

Performance Characteristics:

- High Reliability: VersaMax series products comply with standards such as UL, CUL, and CE, have good anti-interference ability and a wide temperature operating range, and are suitable for harsh industrial environments. As a member of this series, the 151X1207BB55SA01 may also have these characteristics and can operate stably in complex industrial scenarios.

- Hot-Swappable Function: VersaMax modules support hot swapping, allowing I/O modules to be added and replaced while the machine or process is running without affecting on-site wiring. This helps reduce downtime and improve the convenience of system maintenance, and it is that this module also has this function.

- Automatic Addressing: This series has an automatic addressing function, which eliminates the need for traditional configuration and handheld devices, can reduce programming time and workload, and improve the efficiency of system installation and debugging. Therefore, the 151X1207BB55SA01 is likely to have this feature as well.

Industry Applications:

- Chemical and Pharmaceutical Industry: It can be used to monitor and control various parameters in chemical reaction processes. For example, in the antibiotic fermentation process, it can monitor pH value and dissolved oxygen to ensure a stable fermentation environment. It can also be used for automatic control of pharmaceutical production lines to realize precise measurement, mixing, filling and other links in the drug production process.

- Oil and Gas Industry: In oil refineries, it can control pumps, valves, sensors and other equipment to realize the automation of the production process. It can also be used in the exploration and transportation of oil and gas to monitor and control related equipment, ensuring the safety and stability of the production process.

- Electric Power Industry: It can be applied to thermal power and hydropower monitoring and control systems, as well as boiler auxiliary interlocking systems, coal conveying, chemical water treatment, dust removal and other control systems. It can also be used in power transmission and transformation four-remote control systems to realize automatic monitoring of power production, transmission and distribution processes.

- Rail Transit Industry: It can be used in signal control systems to realize functions such as train operation monitoring and switch control. For example, the first phase of Shanghai Rail Transit Line 9 selected the VersaMax series as RI/O and I/O modules to automatically monitor and manage electromechanical equipment such as ventilation fans and air valves in all stations and section tunnels.

- Metallurgical Industry: It can be applied to blast furnace feeding, coking, steelmaking, continuous casting, continuous rolling and other auxiliary control systems. Through precise control of metallurgical equipment, it can improve production efficiency and product quality, while ensuring the safety and reliability of the production process.

- Food and Beverage Industry: In the food packaging process, it can be used for temperature control, product weighing, etc., such as heat-sealing temperature control in food packaging, product weight detection and sorting. It can also be used for controlling various equipment on food and beverage production lines to realize an automated production process.

- Water Treatment Industry: It can monitor parameters such as pump outlet pressure, turbidity and residual chlorine, optimize dosing and backwashing strategies, and realize automatic control of water treatment facilities such as sewage treatment plants and water purification plants, ensuring water quality and water treatment efficiency.

- Building Materials Industry: It can be used in kiln control systems and cement plant mill kiln control systems, etc. It can precisely control parameters such as temperature, pressure and flow in the production process of building materials, ensuring stable product quality and improving production efficiency.

Reviews

Be the first to review “GE 151X1207BB55SA01 VersaMax Series Industrial Control Module” Cancel reply

Shipping & returns

Free and fast shipping

Cras condimentum sapien eu congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Easy returns

Aliquam dapibus placerat dui, ac ullamcorper odio dapibus eget. Sed aliquam leo pellentesque est blandit, sit amet posuere dui maximus.

Order tracking

Nullam lacinia iaculis erat ut fermentum. Praesent volutpat sagittis dictum. Mauris quis egestas dui, eu iaculis turpis.

24/7 customer support

Congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Reviews

There are no reviews yet.