Product information

Reviews

Shipping & returns

Product information

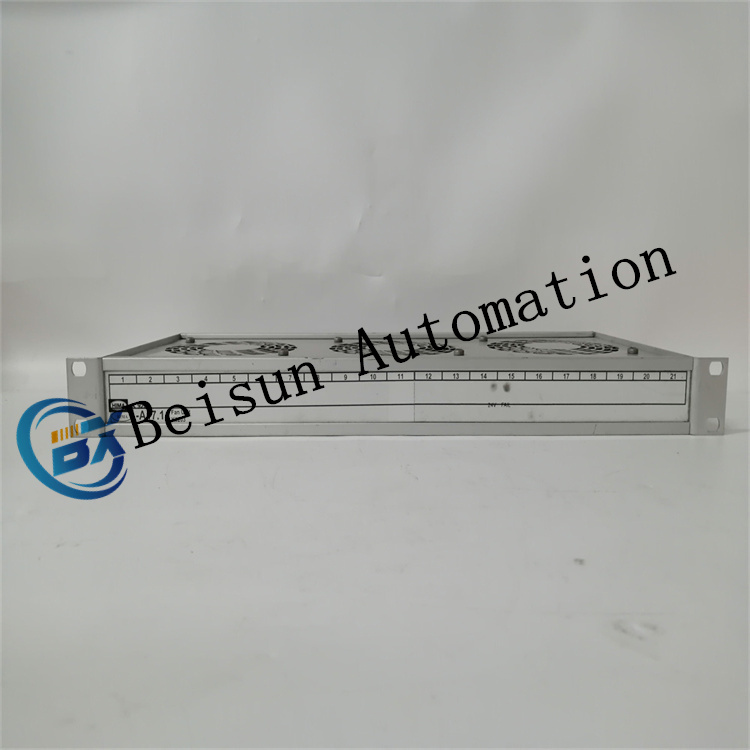

GE 151X1235BC01SA01 10-slot Ethernet switch

First, it has stronger adaptability to industrial environments

Wide-temperature design: GE industrial switches are typically optimized for harsh industrial environments and support wide-temperature operation (such as -40 ° C to 75 ° C), making them suitable for high or low-temperature scenarios in metallurgy, mines, outdoor areas, etc. In contrast, some similar switches may be more appropriate for commercial environments with a narrower temperature resistance range.

Anti-interference capability: Made of industrial-grade materials and with protective design, it has the ability to resist vibration and electromagnetic interference, and can work stably in industrial sites with strong electromagnetic interference. It is suitable for connecting PLCS, sensors and other equipment with high reliability requirements.

Second, modular design is more flexible

Slot expansion advantages: The 10-slot design supports the simultaneous access of more modules (such as Ethernet modules, serial port modules, security modules, etc.), and can flexibly adapt to the connection requirements of multiple devices and multiple protocols in complex industrial networks. For example, in the petrochemical scenario, multiple Ethernet modules can be inserted simultaneously to connect scattered sensors, and then connected to old equipment through serial port modules to achieve a hybrid network architecture.

Customized configuration: Users can freely combine modules according to their actual needs. For instance, they can add redundant power modules to enhance system reliability or insert optical fiber modules to achieve long-distance transmission. However, some switches of the same type may have fewer slots or limited module types, resulting in lower expansion flexibility.

Third, it has better compatibility with GE industrial systems

Ecological integration advantages: As a product under GE, it can be natively compatible with GE’s PLCS (such as the VersaMax series), industrial control systems (such as Proficy), motor protection relays (such as the 369 series), etc., without the need for additional protocol conversion, reducing the complexity of system integration. For instance, in the power monitoring system, it can be seamlessly integrated with GE’s SCADA system directly, resulting in higher data transmission efficiency.

Protocol support targeting: Particularly optimized support for industrial protocols (such as Modbus, EtherNet/IP), suitable for industrial automation networks led by GE. However, other brand switches may require additional configuration to be compatible with GE protocols, posing compatibility risks.

Fourth, the reliability and redundancy design are more complete

Power redundancy: Supports dual power module redundancy configuration. When the main power supply fails, it can automatically switch to reduce downtime, making it suitable for scenarios with high continuity requirements (such as mine hoists and oil pipeline transportation).

Network redundancy Protocol: Supports GE-specific network redundancy protocols (such as ERPS, RSTP). When forming a redundant network with other GE devices, the failover time is shorter (usually <50ms), while the redundancy protocols of some similar switches may need to be manually configured and have lower switching efficiency.

V. Applicable to specific industry scenarios

Energy and heavy industry scenarios: In industries such as metallurgy, power, and petroleum, GE switches are often used as key node devices, in conjunction with GE’s protection relays and monitoring systems. For instance, in the blast furnace control system of a steel plant, they can be linked with GE’s motor protection devices to monitor the motor status in real time and respond quickly to faults.

Renovation of old industrial systems: It has better compatibility with legacy industrial equipment (such as serial port devices and traditional sensors), and communication between new and old equipment can be achieved through module expansion. In contrast, other brand switches may focus more on new network interfaces and have insufficient support for old equipment.

Vi. Features of Service and Technical Support

Industry solution experience: As an industrial giant, GE has accumulated long-term solutions in fields such as energy and transportation, and can provide users with one-stop services from switches to overall systems. For example, in the metro signal system, GE can offer a complete set of solutions including switches, controllers, and software, while other brands may focus more on the sale of individual devices.

Long life cycle support: Industrial-grade products have a relatively long life cycle. GE will provide long-term firmware updates and spare parts support for its switches, which are suitable for projects that require long-term stable operation (such as nuclear power plants and municipal engineering).

Reviews

There are no reviews yet.