Product information

Reviews

Shipping & returns

Product information

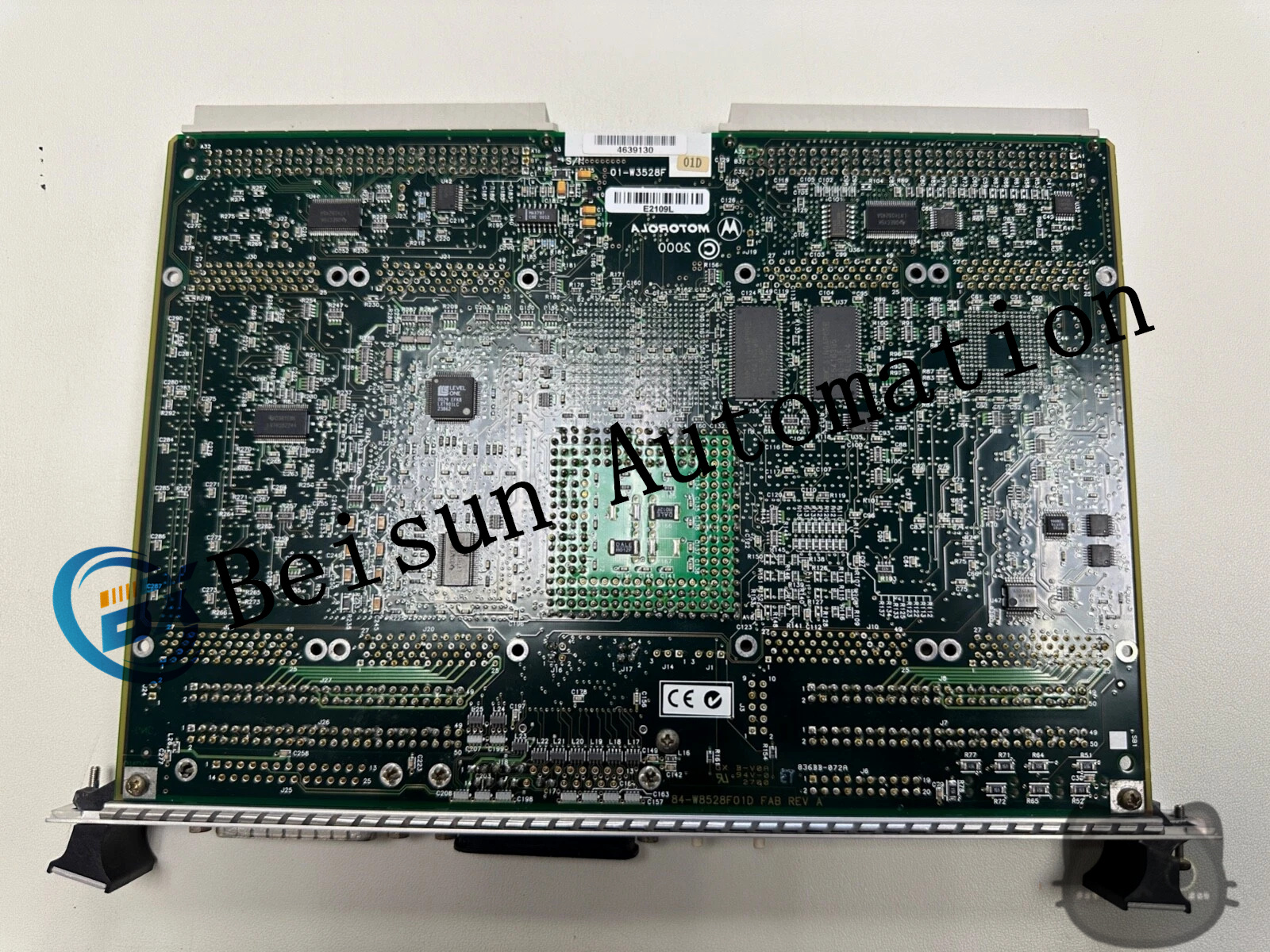

TRICONEX AO2481 PLC Module

The TRICONEX AO2481 module is a high-performance, high-reliability Programmable Logic Controller (PLC) module. The following is a detailed introduction from its characteristics, functions, applications and other aspects:

Characteristics

- Triple Redundancy Architecture: Adopts triple fault-tolerant design, namely Triple Modular Redundancy (TMR) architecture, with three identical processing channels that can process and compare input signals simultaneously. When one of the channels fails, the other two normal channels can continue to work, ensuring the continuous operation of the system in critical tasks, achieving rapid fault switching, and greatly improving the reliability and availability of the system.

- High-performance Processing Capacity: Equipped with a high-end multi-core CPU, it has strong computing power and data processing speed, which can support complex control tasks and logical operations, and easily meet various complex control requirements in industrial automation processes.

- Abundant Memory Resources: It supports up to 4GB RAM and 256GB flash memory, which can store a large amount of program code, data records, historical data, etc., providing sufficient memory support for the stable operation and data processing of the system.

- Support for Multiple Communication Protocols: Supports multiple communication protocols such as Modbus TCP/IP, Profinet, EtherNet/IP, EtherCAT/IP, etc., which can seamlessly integrate with other devices and systems, realize fast data transmission and sharing, and facilitate the construction of complex industrial automation control systems.

- Modular Design: Adopts a compact modular design suitable for Triconex systems, which is convenient for flexible configuration and expansion according to actual needs. More I/O modules, communication modules or other components can be easily added to meet the diversified needs of different industrial application scenarios.

- High Safety Level: Complies with SIL 3 safety standards, with advanced safety functions such as fault detection and isolation capabilities. It can quickly detect faults when the system is abnormal and isolate the faulty part to prevent fault spread, ensuring the safe operation of the entire system.

![]()

Functions

- Safety Logic Operation: It can perform complex safety logic operations, monitor and process various signals in the industrial process in real time, judge the operating status of the system according to preset logical rules, and take corresponding measures in time when abnormal situations occur, such as triggering alarms, cutting off power supplies, stopping equipment operation, etc., to protect key equipment and personnel safety.

- I/O Interface Function: Provides a wide range of analog, digital and serial I/O ports, which can be connected to various sensors, actuators and other external devices, realizing accurate measurement and control of various physical quantities (such as temperature, pressure, flow, liquid level, etc.) in the industrial field, as well as accurate driving and control of actuators such as motors, valves, and pumps.

- Data Communication Function: Through the supported multiple communication protocols, it communicates with other PLCs, DCS systems, upper computer monitoring software, etc., realizing centralized monitoring and management of industrial automation systems, facilitating operators to know the operating status of the system in real time, and performing remote control and parameter adjustment.

- Fault Diagnosis and Alarm Function: Built-in powerful fault self-diagnosis function, which can monitor the operating status of the module itself and connected external devices in real time. Once a fault is found, it will immediately send an alarm signal and record the fault information, which is convenient for maintenance personnel to quickly locate and eliminate faults, reduce system downtime, and improve the maintainability of the system.

Application Fields

- Oil and Gas Industry: Used for the control of key equipment in oil and gas exploration, transportation and processing processes, such as wellhead control, pipeline transportation control, refinery production process control, etc., to ensure the safety and stability of oil and gas production.

- Chemical Industry: In the chemical production process, it performs safety control and logical operations on key equipment such as reactors, distillation towers, and compressors, ensuring the safe operation of the chemical production process and preventing dangerous accidents such as leaks and explosions.

- Power Industry: Suitable for control in power generation, transmission and distribution processes, such as unit control in power plants, automation control in substations, etc., to ensure the stable operation and reliable power supply of the power system.

- Other Industrial Fields: It can also be applied to other industrial fields such as iron and steel, metallurgy, papermaking, pharmaceutical, food and beverage, etc., to perform safety control and automated management on key production equipment and process flows, improve production efficiency and product quality, and reduce production costs and safety risks.

Reviews

Be the first to review “TRICONEX AO2481 PLC Module” Cancel reply

Shipping & returns

Free and fast shipping

Cras condimentum sapien eu congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Easy returns

Aliquam dapibus placerat dui, ac ullamcorper odio dapibus eget. Sed aliquam leo pellentesque est blandit, sit amet posuere dui maximus.

Order tracking

Nullam lacinia iaculis erat ut fermentum. Praesent volutpat sagittis dictum. Mauris quis egestas dui, eu iaculis turpis.

24/7 customer support

Congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Reviews

There are no reviews yet.