- Home

- Product

- Bently Nevada

- BENTLY 1900/65A-00-00-02-00-00 Vibration monitoring instrument

Product information

Reviews

Shipping & returns

Product information

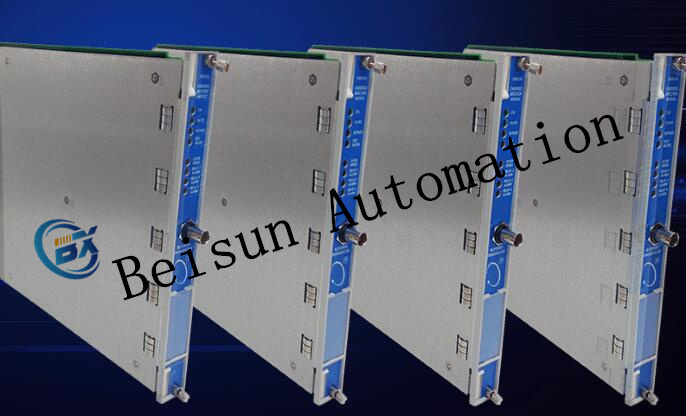

BENTLY 1900/65A-00-00-02-00-00 Vibration monitoring instrument

summarize

The 1900/65A series is designed to meet the high reliability and accuracy requirements for vibration monitoring of rotating machinery in industrial environments. This model is a single channel vibration monitor, which can monitor the vibration status of the equipment in real time and provide critical data support for the maintenance and operation of the equipment.

Technical parameter

Measurement range: peak-to-peak vibration can be measured, usually covering a range of 0-500 mils (mil), which can meet the needs of vibration monitoring of most industrial equipment.

Frequency range: Generally support 5-1000Hz vibration frequency measurement, this range covers the vibration frequency of common rotating machinery, can effectively capture the vibration information of equipment under different operating states.

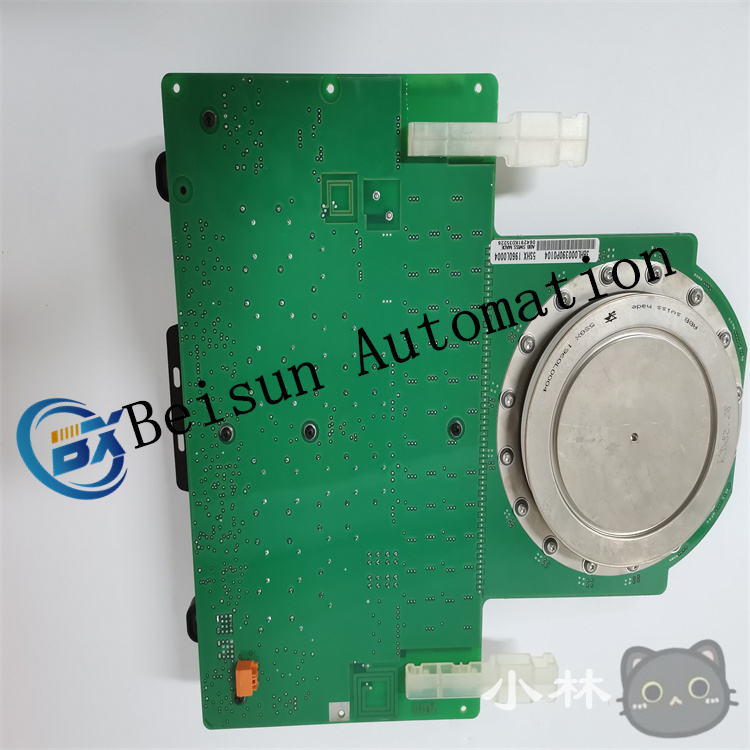

Input type: Accepts the signal input from the accelerometer or speed sensor, can adapt to a variety of types of sensors, with good compatibility.

Output signal: Standard analog output of 4-20mA is available for easy connection with other control systems or data acquisition devices. At the same time, it has relay output function for alarm and trip control, and different alarm thresholds can be set to meet the protection needs of different equipment.

Display: Equipped with a local digital display, can visually display the current measured vibration value, convenient for field operators to check the equipment status at any time.

.jpg)

Functional characteristics

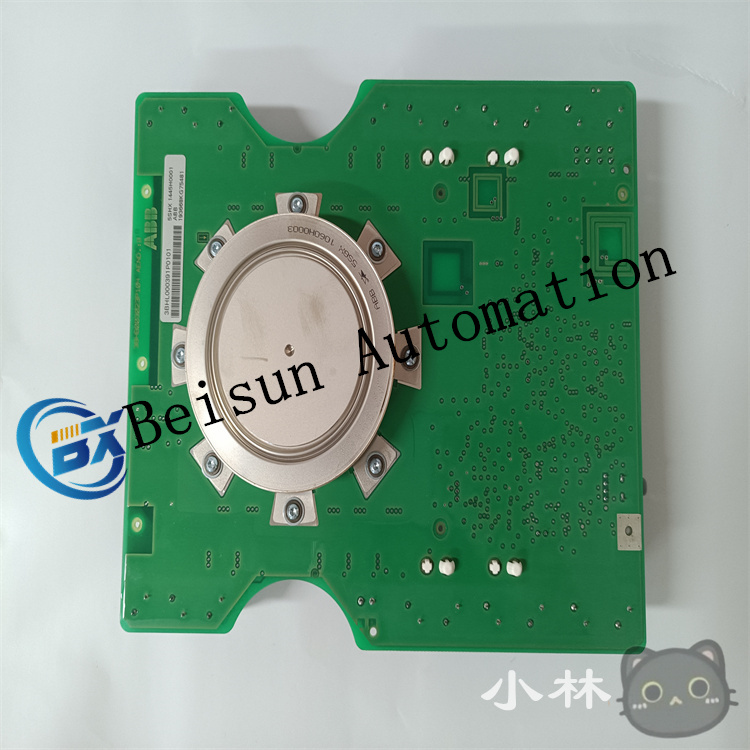

High-precision measurement: The use of advanced signal processing technology and high-precision measurement circuit to ensure the accuracy and reliability of vibration measurement, can timely and accurately reflect the vibration changes of the equipment.

Multiple alarm functions: with flexible alarm setting function, can set high and low alarm thresholds respectively, when the vibration value exceeds the set threshold, the corresponding alarm relay will act, through sound and light alarm or other means to remind the operator to pay attention, in order to take timely measures to prevent equipment damage.

Rugged design: The housing is made of high-strength, corrosion-resistant materials with good dust, water and electromagnetic interference resistance, and can be adapted to harsh industrial environments, such as high temperature, humidity, dust and strong electromagnetic interference sites.

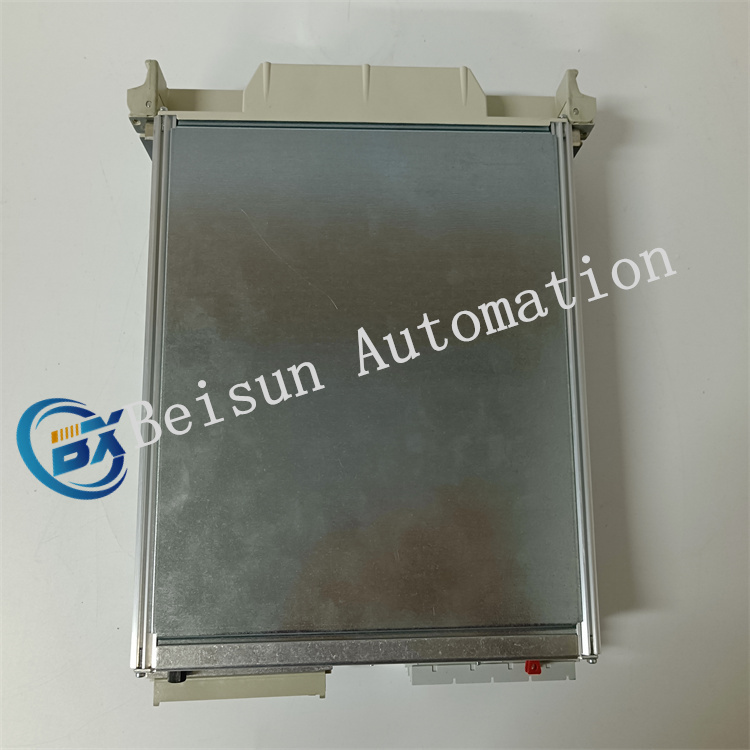

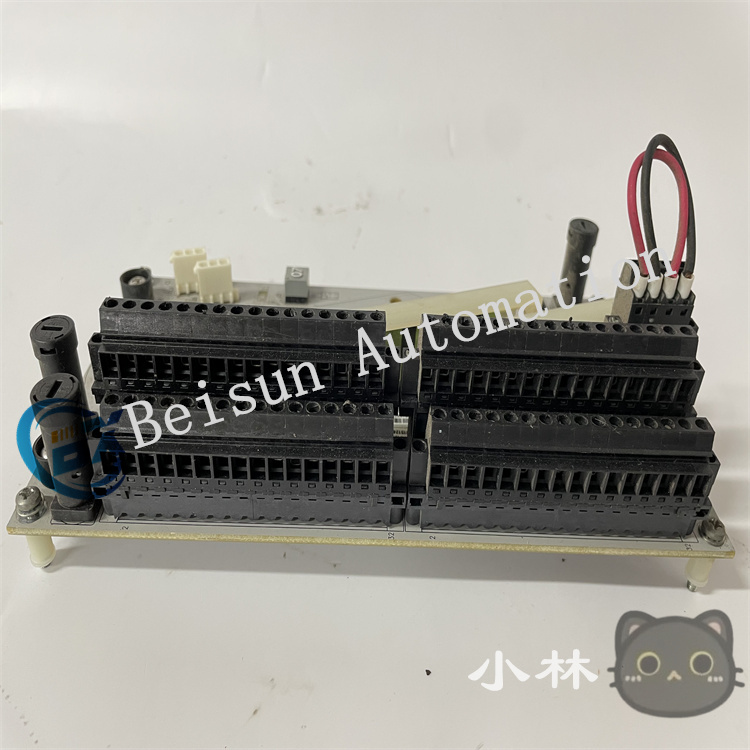

Easy installation and maintenance: compact structure design, flexible installation, panel installation or rail installation, easy to install in different equipment or control cabinets. At the same time, the maintenance of the device is simple. Users can set parameters and diagnose faults on the local interface, reducing the maintenance cost and difficulty.

Application field

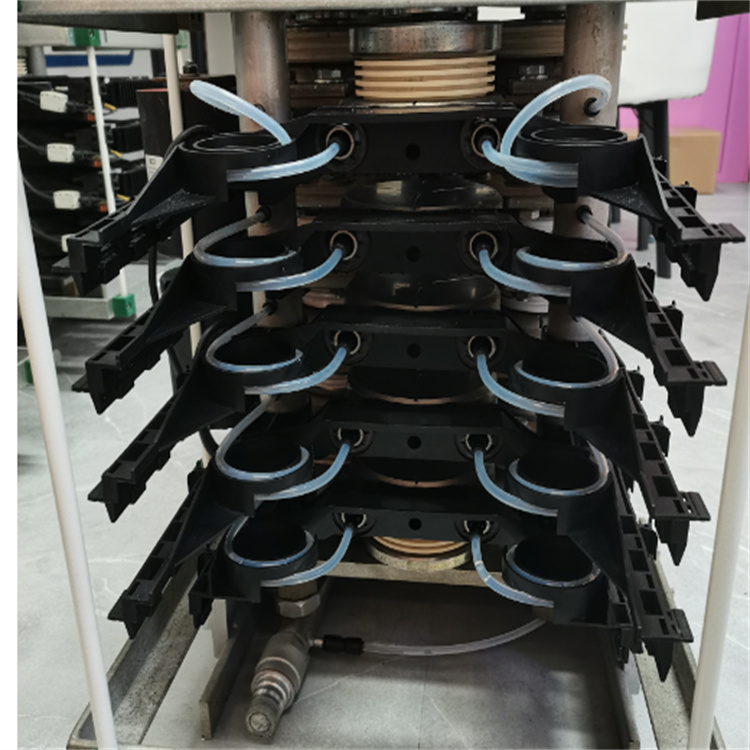

Widely used in petroleum, chemical, electric power, metallurgy, paper and other industries of all kinds of rotating machinery equipment, such as steam turbine, generator, compressor, pump, fan vibration monitoring. Through real-time monitoring and analysis of equipment vibration, the potential faults of the equipment can be found in advance, such as rotor imbalance, bearing wear, shafting misalignment, resonance and other problems, which provides a strong basis for the preventive maintenance of the equipment, thereby improving the operating efficiency of the equipment, extending the service life of the equipment, and reducing the downtime and economic losses caused by equipment failure.

Reviews

There are no reviews yet.