Product information

Reviews

Shipping & returns

Product information

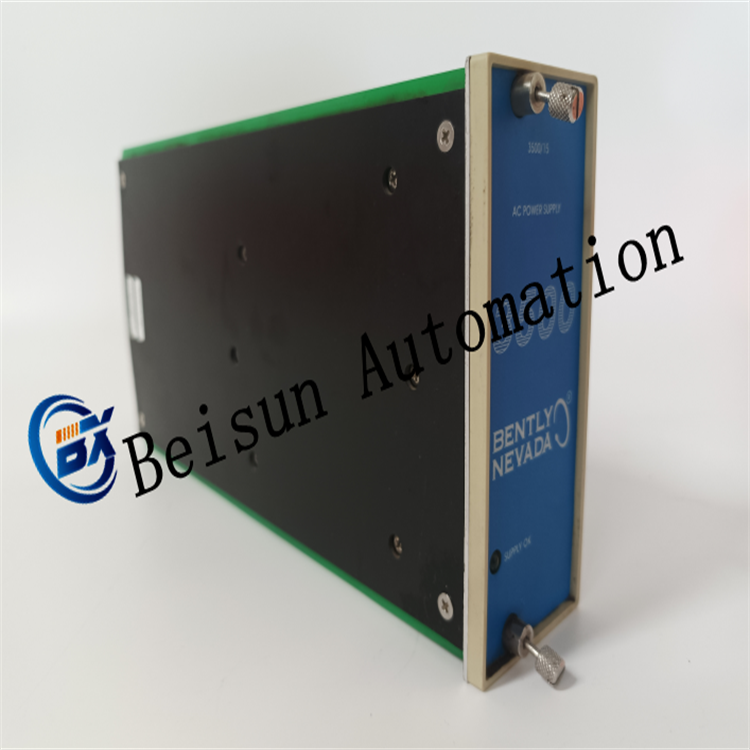

Emerson 1C31147G01 control system module

Technical parameters

Input/output type:

It supports multiple types of input and output signals, commonly including analog input and output and digital input and output. The analog input can receive current signals such as 4-20mA and voltage signals such as 0-10V, and is used to collect continuously changing parameters of on-site equipment, such as temperature, pressure, flow rate, etc. Digital input is used to receive switch signals, such as the start and stop status of equipment, the opening and closing status of valves, etc. The analog output can provide signals such as 4-20mA and 0-10V, which are used to control equipment such as regulating valves and frequency converters. Digital output can control devices such as relays and indicator lights.

Number of channels: Usually, it has multiple input and output channels, which may be in different configurations such as 8 channels, 16 channels, etc. The specific number depends on the actual product specifications to meet the control requirements of industrial production of different scales.

Accuracy:

Analog input and output have high precision, generally reaching ±0.1% – ±0.2%, which can accurately collect and output signals, ensuring the precise control of industrial processes by the control system.

Resolution: The analog part has a relatively high resolution, such as 12-bit or 16-bit, which enables more precise signal processing and captures minute changes in the signal.

Isolation feature: Electrical isolation technology is adopted between the input and output channels and the system power supply as well as other parts. The isolation voltage is usually between 1500V and 2500V, effectively preventing external interference signals from entering the system and avoiding internal system faults from affecting on-site equipment.

Application field

In the power industry, it is used in power production enterprises such as thermal power plants, hydropower stations, and nuclear power plants to monitor and control the operating parameters of key equipment such as generators, steam turbines, and boilers, including temperature, pressure, and rotational speed, as well as to control switchgear to ensure the safe and stable operation of power production.

In the chemical industry, during the chemical production process, real-time monitoring and control of parameters such as temperature, pressure, liquid level and flow rate of various chemical reaction vessels, storage tanks, pipelines and other equipment are carried out to ensure the safety of the chemical production process and the stability of product quality.

The oil and gas industry: In the processes of oil extraction, oil refining, and natural gas processing, the operational status of equipment such as oil Wells, pipelines, and refining and chemical facilities is monitored and controlled to achieve efficient production and transportation of oil and gas.

Water treatment industry: In waterworks and sewage treatment plants, monitoring and control are carried out on water levels, water quality, pumps, valves and other equipment and parameters to achieve rational utilization of water resources and compliance with sewage discharge standards.

Reviews

There are no reviews yet.