Product information

Reviews

Shipping & returns

Product information

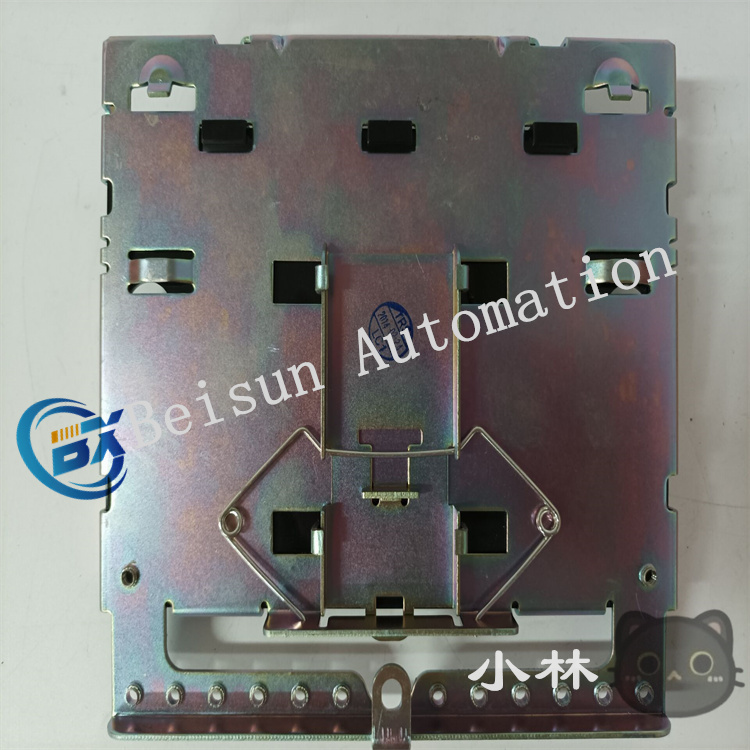

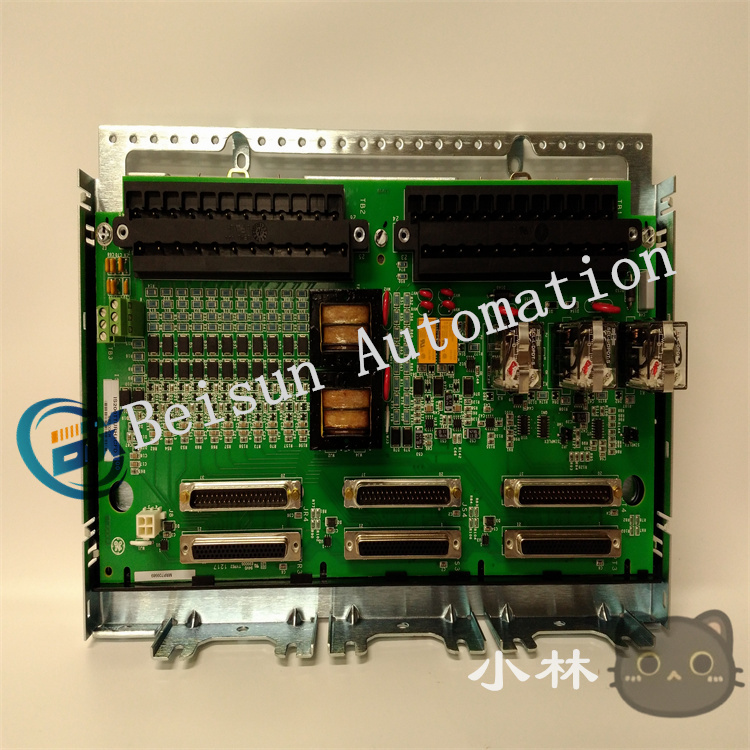

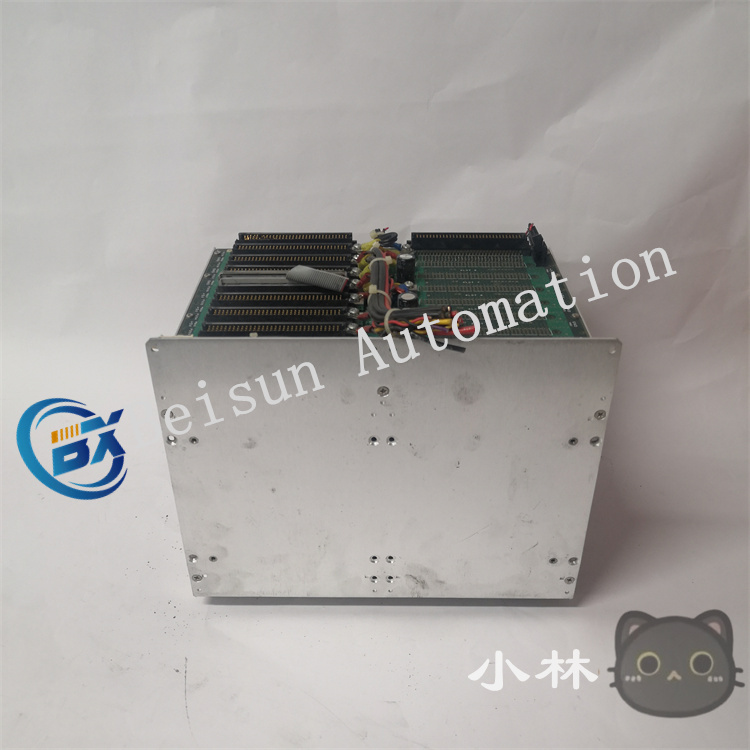

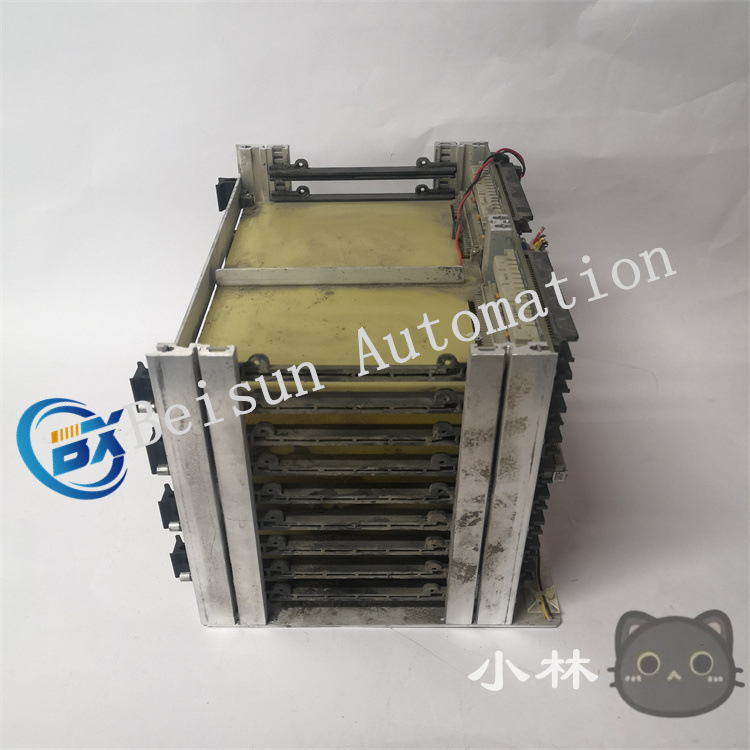

Emerson 5X00044G01 module

Application field

In the power industry, in power plants, it can be used to monitor and control various parameters of generator sets, such as monitoring the speed, temperature, pressure and other parameters of steam turbines, as well as controlling the excitation system and speed regulation system of generators, to ensure the stable operation of generator sets. In substations, electrical parameters such as busbar voltage, line current, and power factor can be collected to achieve automated monitoring and protection of the substation. For instance, fault diagnosis and tripping control can be carried out based on the collected data to ensure the safe and reliable operation of the power system.

In the chemical industry, during the chemical production process, various process parameters can be precisely controlled, such as the temperature, pressure, and liquid level of the reaction vessel, as well as the flow rate and composition of the fluid in the pipeline. By monitoring and adjusting these parameters in real time, the stability of the chemical production process and the consistency of product quality can be ensured. At the same time, safety protection for chemical production equipment can also be achieved, such as promptly activating the emergency shutdown system in case of abnormal situations.

Water treatment industry: In waterworks, it can be used to monitor and control various links in the water treatment process, such as the water quality parameters of raw water (turbidity, pH, hardness, etc.), the water level of sedimentation tanks, the operating status of filtration equipment, etc., to achieve automatic control of the water treatment process and improve the quality of water supply. In sewage treatment plants, the water quality changes of sewage can be monitored, and the operation of sewage treatment equipment, such as aeration equipment and sludge treatment equipment, can be controlled to ensure that sewage is discharged up to standard.

In the metallurgical industry, it can be applied in production processes such as blast furnace ironmaking and converter steelmaking in steel plants. It can monitor and control parameters such as temperature, pressure and composition inside the furnace in real time, optimize the production process and improve the quality and output of steel products. It can also be used to control the operation of metallurgical equipment, such as the pulling speed of continuous casting machines and the vibration of molds, to ensure the smooth progress of the production process.

Papermaking industry: It can monitor and control parameters such as pulp concentration, flow rate, temperature, as well as paper basis weight, moisture content, and strength during the papermaking process, achieving automated and refined management of papermaking production, improving paper quality and production efficiency, while reducing production costs and energy consumption

Reviews

There are no reviews yet.