Product information

Reviews

Shipping & returns

Product information

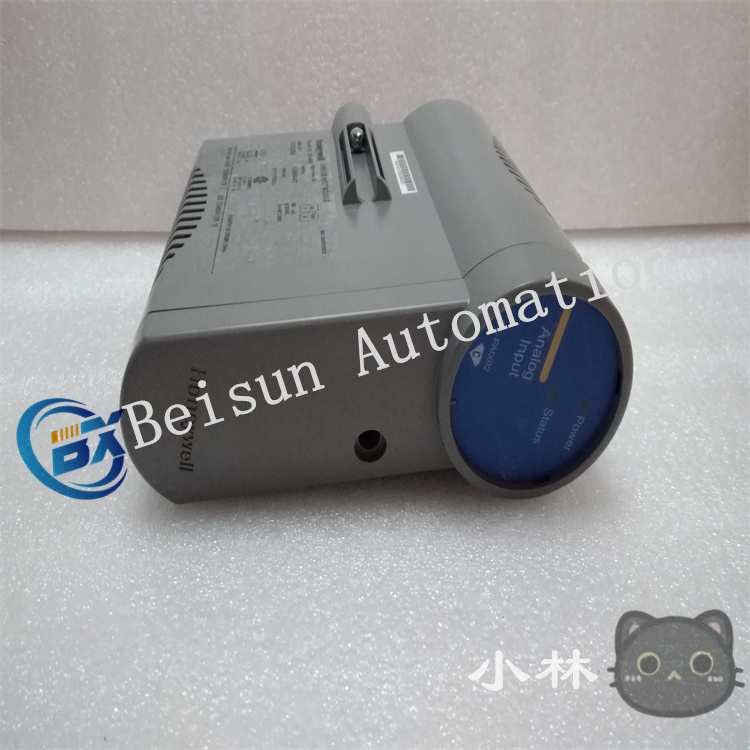

Honeywell CC-PAIX 02-51405038-475 Automation Control System Module

Technical parameters

Input signal accuracy: It has a relatively high analog-to-digital conversion accuracy, generally reaching 12 bits or higher, and can precisely convert analog signals into digital signals to accurately reflect the minute changes in the input signal. For example, for an input signal of 0-10V, a 12-bit precision analog-to-digital converter can increase its resolution to approximately 2.44mV and be able to precisely capture the subtle fluctuations of the signal.

Power supply specification: Usually, it requires a DC power supply. The common power supply voltage is 24V DC, and it has a certain power supply ripple suppression capability to ensure stable operation under different power supply conditions. The power consumption of the module is generally low, which can meet the long-term operation requirements of industrial sites while saving energy.

Communication interface type: Supports standard industrial communication protocols, such as Profibus-DP, Modbus TCP, etc., and communicates with other devices through corresponding communication interfaces (such as RS-485, Ethernet interface, etc.). This can be conveniently integrated into various automatic control systems, and interact with controllers such as PLC and DCS as well as upper-level computer monitoring software for data exchange, thereby achieving remote monitoring and control functions.

Application scenarios

Industrial process control: In industrial fields such as chemical engineering, petroleum, and metallurgy, it is used to collect various process parameters, such as temperature, pressure, flow rate, liquid level and other analog signals, providing accurate data for process control systems, so as to achieve precise control and optimization of the production process, and ensure the safe, stable and efficient operation of the production process.

Intelligent factory automation: In an intelligent factory, it can be used to connect various intelligent sensors and actuators to achieve real-time monitoring and control of production equipment, logistics systems, etc. By collecting a large amount of analog data and working in coordination with other automated equipment, the automation, intelligence and informatization management of the production process can be achieved, thereby enhancing the production efficiency and product quality of the factory.

Energy management system: In the field of energy management, it can be used to collect analog signals such as voltage, current and power in the power system, as well as energy consumption data of industrial equipment. Through the analysis and processing of these data, real-time monitoring, analysis and optimization of energy consumption can be achieved, helping enterprises reduce energy costs and improve energy utilization efficiency.

Reviews

There are no reviews yet.