Product information

Reviews

Shipping & returns

Product information

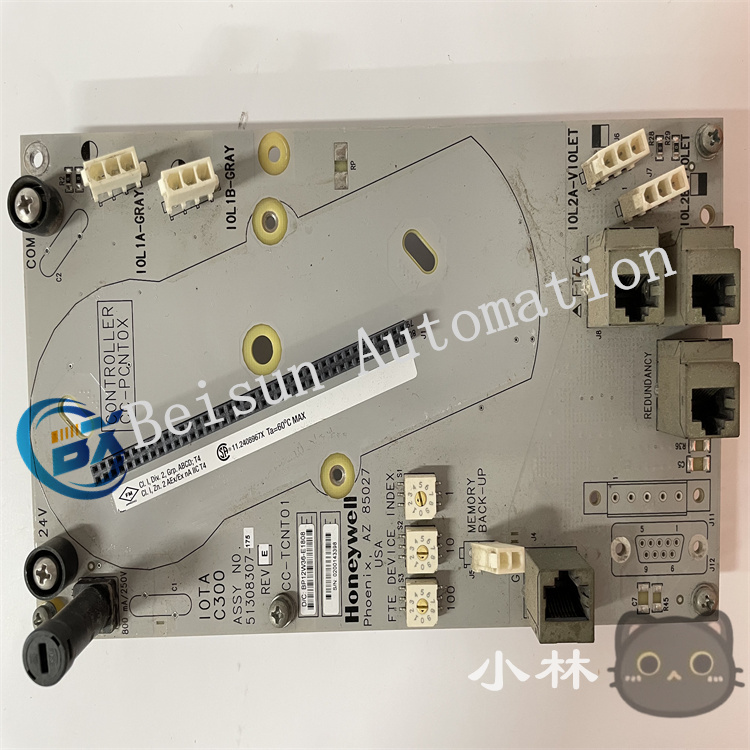

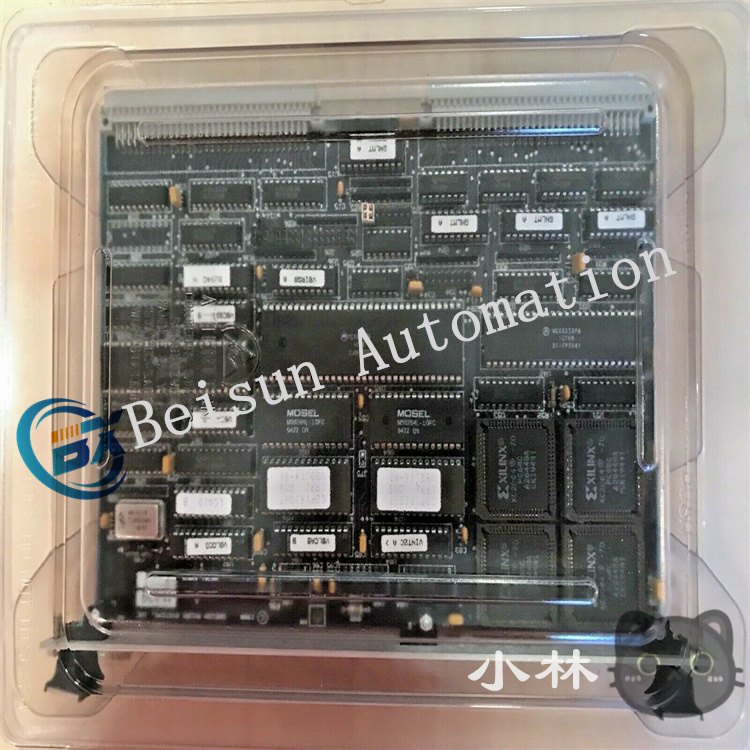

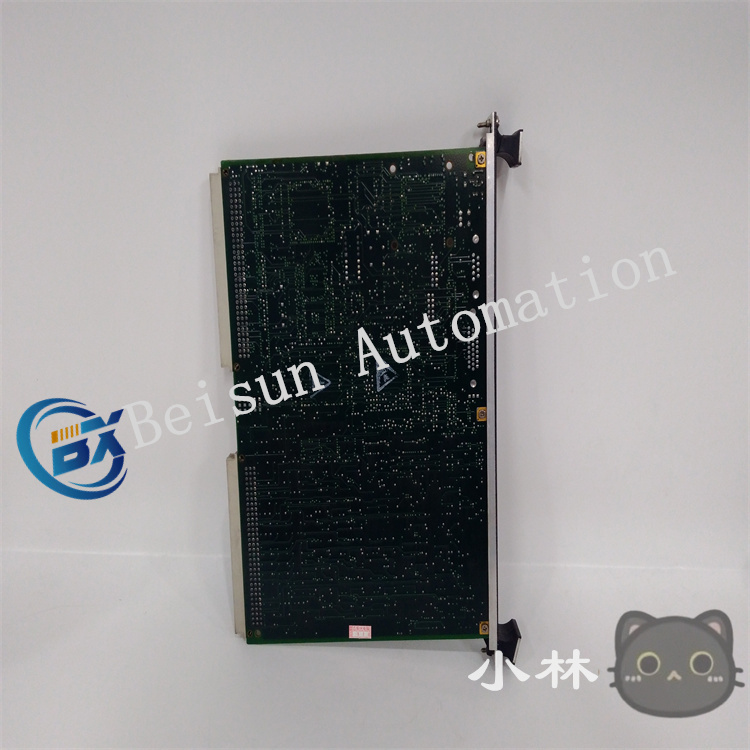

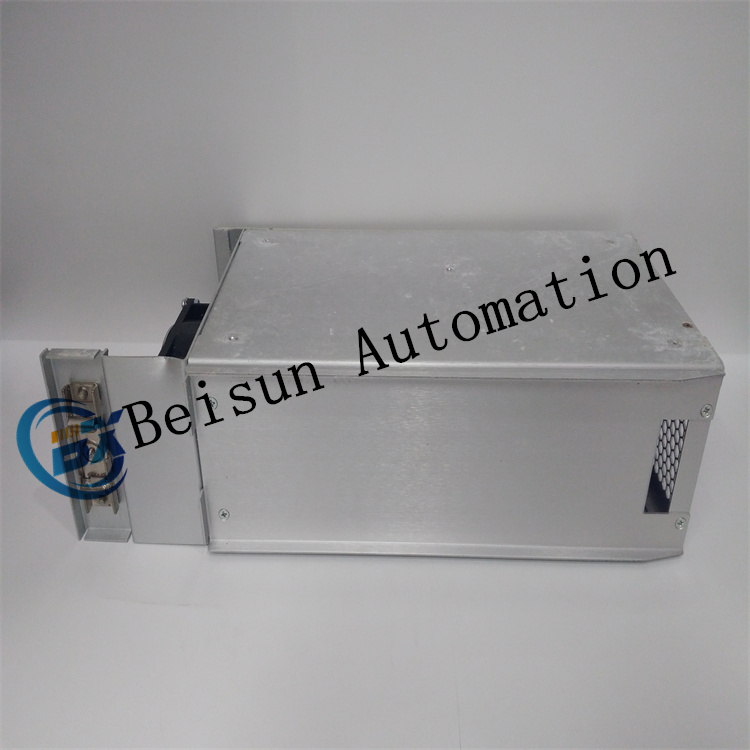

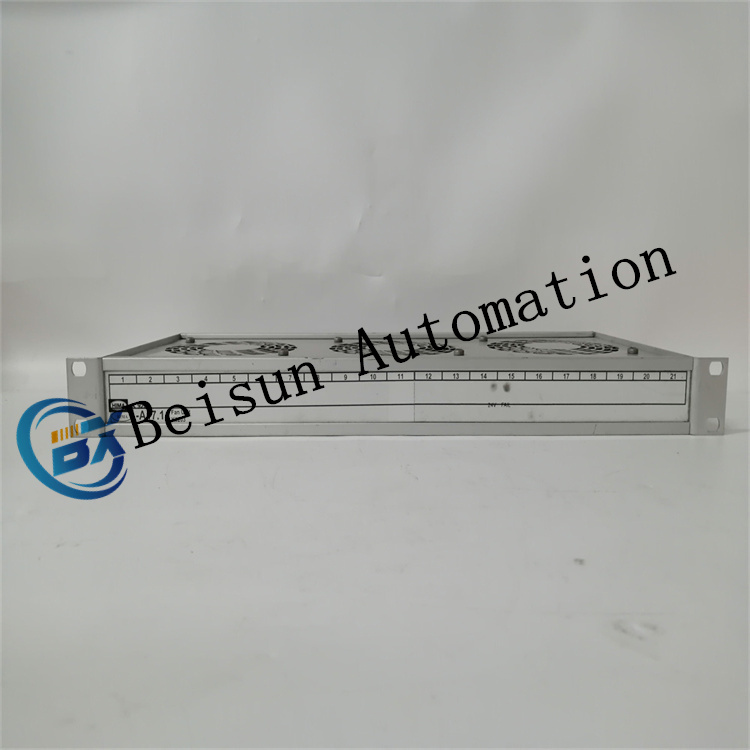

Honeywell CC-TAID01 Analog input module

Functional characteristics

High-precision conversion: By adopting high-precision A/D converters, analog signals from sensors, transmitters and other devices can be accurately converted into digital signals suitable for use by PLCS or other control systems, ensuring the accuracy of data acquisition.

Multiple input types and ranges: Supports voltage input and current input, with input ranges including -10V to + 10V, -20mA to + 20mA, etc., which can adapt to the output signals of various sensors.

High reliability: Utilizing industrial-grade components and undergoing rigorous testing and verification, it can operate stably in harsh industrial environments and has strong anti-interference capabilities.

Easy to use: It provides abundant software and hardware resources, facilitating users’ development and usage, and reducing the difficulty of system integration.

Scalability: Supports modular expansion, allowing for combination and expansion based on different application requirements to meet the demands of control systems of various scales.

Technical parameters

Number of channels: 4 channels, capable of simultaneously collecting 4 analog signals.

Resolution: 16 bits, capable of precisely distinguishing minute changes in analog signals.

Update rate: 1000Hz, which means that the analog signal can be sampled and converted 1000 times per second, enabling timely tracking of signal changes.

Power supply: 24V DC. It is powered by DC power supply to ensure the stability of the module’s operation.

Operating temperature: -40°C to 85°C, adaptable to a wide temperature range, and can be used in various industrial environments.

Application field

Process control: In industries such as chemical engineering, petrochemicals, and power, it is used to monitor and regulate analog parameters such as temperature, pressure, flow rate, and liquid level during the production process, ensuring the efficient and stable operation of the production system.

Data acquisition: Widely applied in various scenarios where analog data needs to be collected, such as industrial automated production lines, laboratory equipment, environmental monitoring systems, etc., it provides accurate data support for data analysis and decision-making.

Equipment status monitoring: It can be used to monitor the operating status of equipment. By collecting analog signals such as vibration, temperature, and current of the equipment, abnormal conditions of the equipment can be detected in a timely manner, achieving fault early warning and preventive maintenance.

Process parameter control: In manufacturing and other fields, precise control of key parameters in the production process is carried out, such as pressure and temperature control of injection molding machines, tension control of textile machinery, etc., to improve product quality and production efficiency.

Reviews

There are no reviews yet.