Product information

Reviews

Shipping & returns

Product information

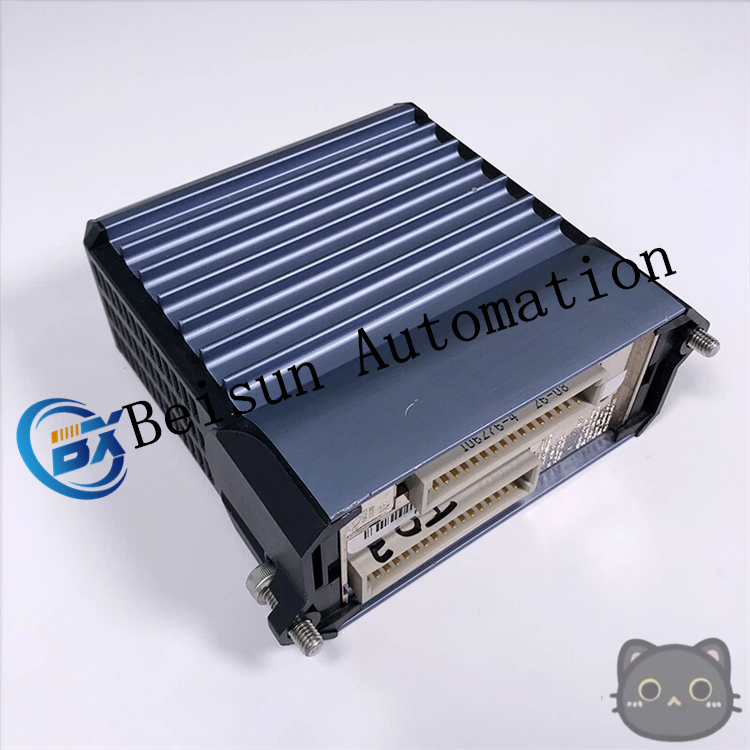

Foxboro FBM201B analog input interface module

In the petrochemical industry, during the production process of petrochemicals, precise monitoring and control of various process parameters are required. The FBM201B can be connected to pressure sensors, temperature sensors, flow sensors, etc. It converts the analog signals collected by these sensors into digital signals and transmits them to the control system. For instance, in crude oil distillation units, by monitoring parameters such as temperature and pressure at different parts and using FBM201B for signal collection and processing, it helps operators promptly understand the status of the production process, achieve precise control over the distillation process, and ensure the stability of product quality.

In the power industry, FBM201B can be used in power plants and substations to monitor the operating parameters of generators, the voltage and current of the power grid, etc. It can collect analog signals from devices such as voltage transformers and current transformers, providing accurate data support for the automatic control and protection of power systems. For instance, in the relay protection devices of power systems, the FBM201B can monitor power parameters in real time. When abnormal situations occur, it promptly sends signals to the protection devices, triggering protection actions to ensure the safe and stable operation of the power system.

Metallurgical industry: In the steel production process, FBM201B can be applied to the monitoring systems of equipment such as blast furnaces and converters. It can be connected to various detection instruments, such as furnace temperature sensors, pressure sensors, composition analyzers, etc., to collect various data during the production process in real time. Through the analysis and processing of these data, operators can promptly adjust the production process, optimize the production flow, and enhance the quality and production efficiency of steel products. For instance, during the blast furnace ironmaking process, by monitoring parameters such as temperature, pressure and permeability inside the furnace, and using FBM201B for signal collection and processing, precise control of the blast furnace’s operating status can be achieved, ensuring the stable and smooth operation of the blast furnace.

The pharmaceutical industry: During the pharmaceutical production process, the control requirements for environmental parameters and process parameters are extremely strict. The FBM201B can be used to monitor environmental parameters such as temperature, humidity and pressure in clean rooms, as well as the operating parameters of production equipment such as reactors and centrifuges. By precisely collecting these analog signals and transmitting them to the control system, precise control and quality monitoring of the pharmaceutical production process can be achieved, ensuring the quality and safety of the drugs. For instance, during the freeze-drying process of pharmaceuticals, the FBM201B is utilized to monitor parameters such as temperature and pressure inside the freeze dryer, precisely controlling the freeze-drying process to ensure the stability and effectiveness of the pharmaceuticals.

Reviews

There are no reviews yet.