Product information

Reviews

Shipping & returns

Product information

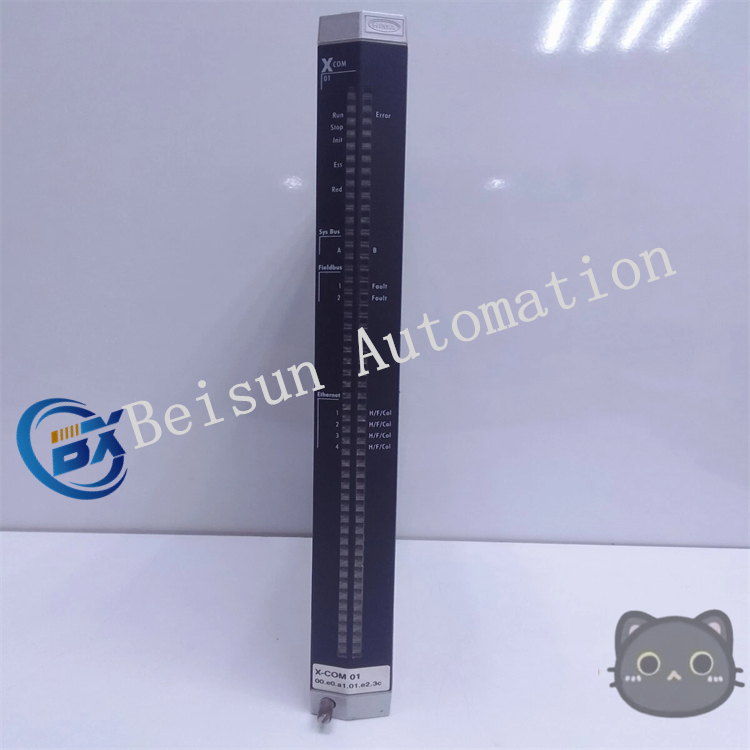

HIMA X-COM 01 High-Performance Communication Module

Functional Uses

- System Communication Connection: Used for communication connections between various components or systems within the HIMA safety system, which can be seamlessly integrated with HIMA’s safety PLCs, safety relays and other devices to realize data exchange and collaborative work between devices.

- Signal Transmission and Conversion: Supports multiple types of input and output signals, and can transmit and convert signals from different devices, enabling mutual recognition and communication between various devices, so as to meet the requirements of various signals and devices such as digital input and digital output.

- Control Logic Programming: With programming capability, users can customize control logic and algorithms according to the actual needs of industrial automation applications, so as to realize flexible control of the production process and meet the personalized control requirements of different production scenarios.

Technical Features

- Communication Protocol Support: Supports multiple communication protocols, such as Modbus TCP/IP, OPC-UA, etc., and also supports HIMA’s internal proprietary protocols, which can easily exchange data with other devices, controllers, computers or monitoring systems using standard protocols to ensure real-time information sharing.

- High-Speed Data Transmission: It has a high data transmission rate. For example, some models can reach 100Mbps, which can quickly transmit large amounts of data, ensure efficient communication between various devices in the industrial automation system, reduce data transmission delay, and improve the overall response speed of the system.

- High Reliability and Stability: It adopts measures such as electrical isolation technology to effectively reduce electrical interference and failure risks and improve system safety. The module has passed strict tests and certifications, such as CE, UL, FCC, etc., complies with international safety standards, and can operate stably in harsh industrial environments to ensure the reliable operation of the system.

- Flexible I/O Configuration: Provides rich digital or analog I/O options, which can be flexibly configured according to specific application scenarios and equipment requirements to meet the requirements of different industrial automation systems for input and output signals.

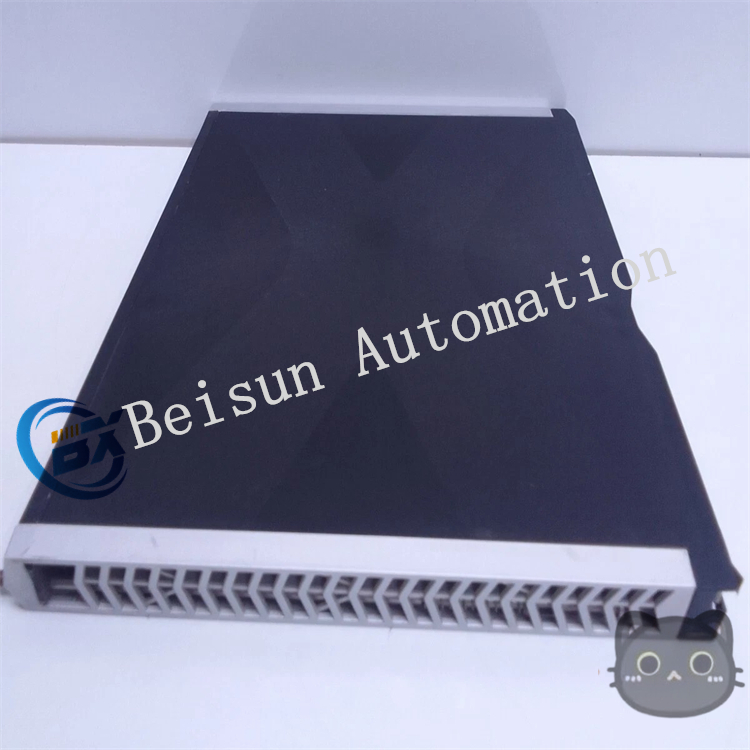

- Easy Installation and Maintenance: It provides cable management functions, such as cable clamps, labels and wiring arrangements, to ensure orderly and safe cable connections. At the same time, it has the function of quick connection and disassembly, which simplifies the installation and maintenance process and reduces operation costs and maintenance time.

Technical Parameters

- Power Parameters: It is usually powered by DC power supply. The common supply voltage is 24VDC, and the current input is generally between 0.25A and 0.46A.

- Environmental Parameters: The operating temperature range is generally -20℃ to +70℃, and the protection grade is IP20, which can meet the use requirements of most industrial environments.

- Dimensions and Weight: The module is approximately 23cm × 2.92cm × 31cm in size and weighs about 1.3kg. Its compact design can save space in the control cabinet and facilitate installation and layout.

Application Fields

- Industrial Automation Production Lines: In various industrial automation production lines such as automobile manufacturing, electronic equipment production, food and beverage processing, it is used to connect various equipment in the production line, such as robots, conveyors, machining centers, etc., to realize collaborative work between equipment and automatic control of the production process.

- Petroleum and Chemical Industry: In the processes of oil extraction, oil refining, chemical production, etc., it is used to connect various monitoring equipment, control valves, pumps, etc., to realize real-time monitoring and safety control of the production process, and ensure the stable operation of the production process and the safety of personnel and equipment.

- Power Industry: In power systems such as power plants and substations, it is used to connect monitoring systems, protection devices, automatic control equipment of power equipment, etc., to realize stable operation and fault monitoring of the power system, and ensure the reliability and safety of power supply.

Reviews

Be the first to review “HIMA X-COM 01 High-Performance Communication Module” Cancel reply

Shipping & returns

Free and fast shipping

Cras condimentum sapien eu congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Easy returns

Aliquam dapibus placerat dui, ac ullamcorper odio dapibus eget. Sed aliquam leo pellentesque est blandit, sit amet posuere dui maximus.

Order tracking

Nullam lacinia iaculis erat ut fermentum. Praesent volutpat sagittis dictum. Mauris quis egestas dui, eu iaculis turpis.

24/7 customer support

Congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Reviews

There are no reviews yet.