Product information

Reviews

Shipping & returns

Product information

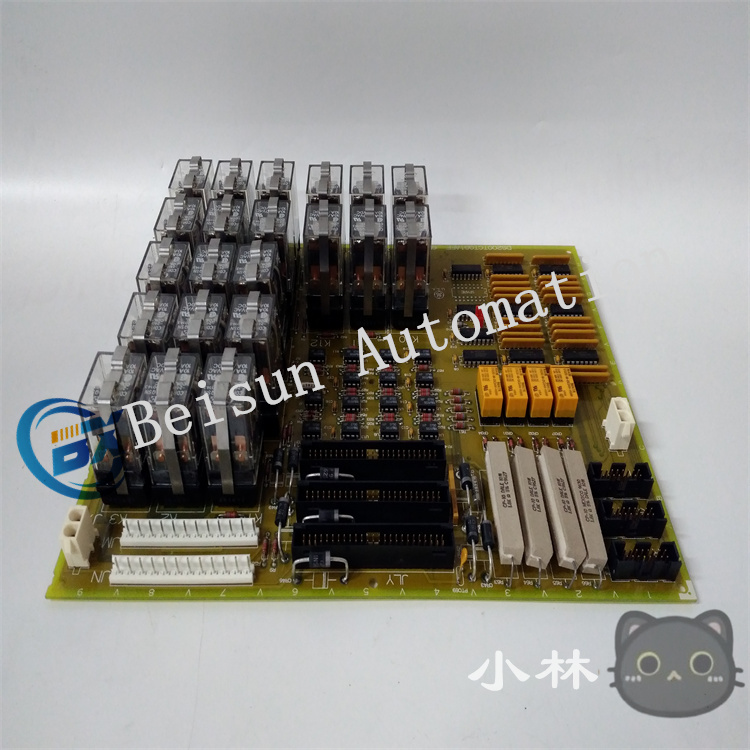

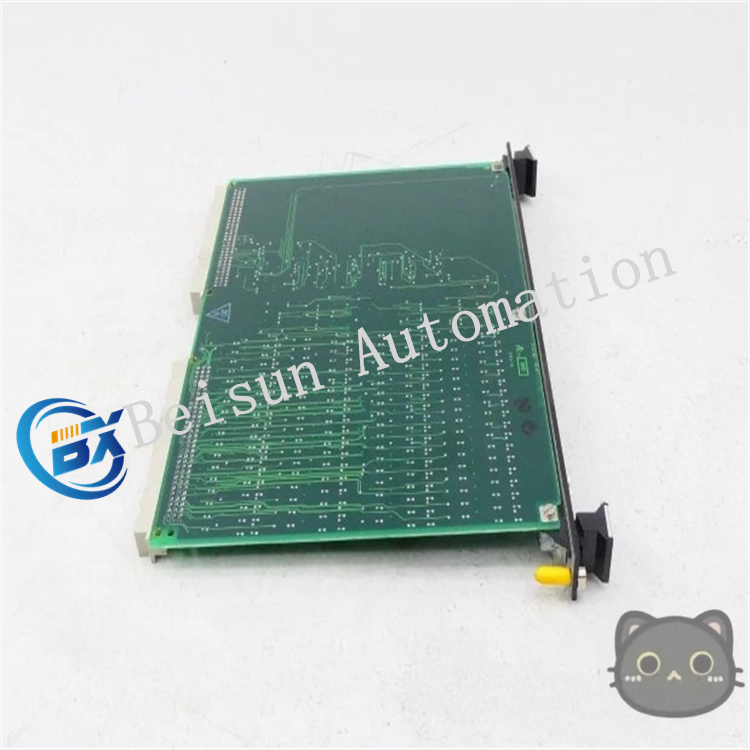

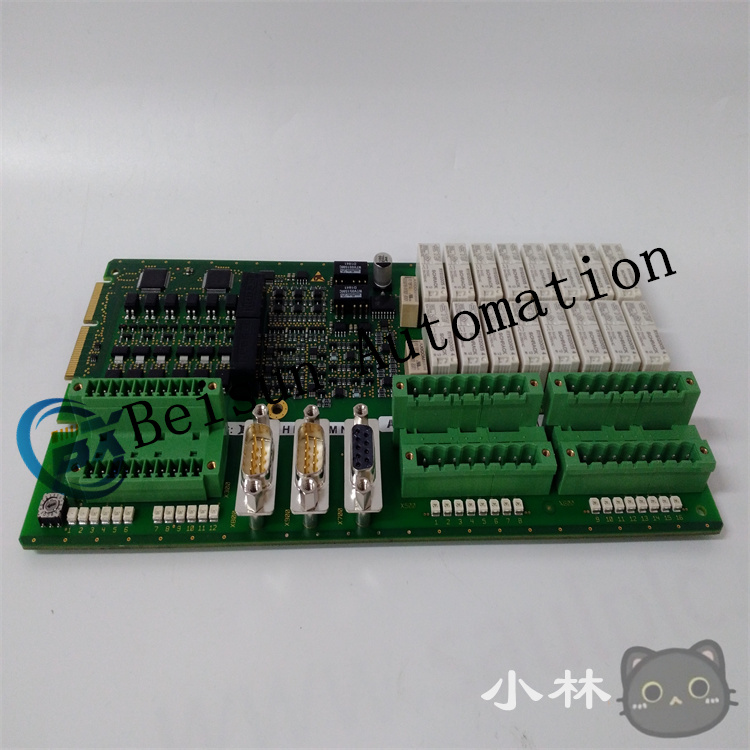

GE DS200FCSAG2A Current Sensing Feedback Board

The GE DS200FCSAG2A current sensing feedback board features high-precision current monitoring and other functional characteristics, making it suitable for various industrial scenarios. Here is a detailed introduction:

Functional Characteristics

- High-precision current monitoring: It can accurately monitor the current in the static starter power conversion cabinet, providing precise current data for the system. This ensures the accuracy of current control and helps improve the performance and efficiency of gas turbine generator systems.

- Real-time feedback: Adopting advanced sensor technology, it can monitor current in real-time and feed back information. This allows the system to make timely adjustments based on current conditions, reducing downtime, improving production efficiency, and achieving energy savings.

- High reliability: Manufactured by General Electric, it boasts reliable quality and a robust structural design. It can adapt to a wide temperature range, operate stably in harsh industrial environments, and reduce the probability of failures.

- Easy integration: Specifically designed for integration with the LS2100 series static starter control system, it can seamlessly integrate into GE’s advanced drive systems. This facilitates installation and maintenance, optimizes dynamic control loops, and ensures stable system operation under different loads and conditions.

Technical Parameters

- Dimensions and weight: Approximately 22.8cm × 12.6cm × 2cm in size; weighs about 0.18kg.

- Number of channels: 12 channels.

- Common-mode voltage range: +5V DC.

- Maximum lead resistance: 15Ω.

- Analog output current: 0 – 20mA.

- Operating temperature: -30℃ to 65℃.

- Operating frequency: 50 or 60Hz.

Application Fields

- Power generation industry: It is mainly used in gas turbine generator systems and is an important component of the LS2100 series static starter power conversion cabinet. It can improve the stability and efficiency of power generation systems and ensure precise current control and monitoring during power generation.

- Other industrial fields: It is also suitable for other industrial scenarios requiring precise current measurement and control, such as variable-speed AC drive systems supporting gas turbine generators in manufacturing, automation, and other industries. It ensures the stable operation of related equipment.

Working Principle

Current measurement is typically achieved based on principles such as electromagnetic induction or the Hall effect. The internal current sensor detects changes in current in the circuit, converts the current signal into a measurable electrical signal (such as voltage), and then processes it through signal processing circuits on the board (e.g., amplification, filtering). The processed signal is transmitted to the system’s control unit. The control unit performs real-time monitoring and control of the system based on the received current feedback signal. When an abnormal current occurs, it can promptly adjust relevant parameters or issue an alarm signal to ensure the safe and stable operation of the system.

Reviews

Be the first to review “GE DS200FCSAG2A Current Sensing Feedback Board” Cancel reply

Shipping & returns

Free and fast shipping

Cras condimentum sapien eu congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Easy returns

Aliquam dapibus placerat dui, ac ullamcorper odio dapibus eget. Sed aliquam leo pellentesque est blandit, sit amet posuere dui maximus.

Order tracking

Nullam lacinia iaculis erat ut fermentum. Praesent volutpat sagittis dictum. Mauris quis egestas dui, eu iaculis turpis.

24/7 customer support

Congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

.jpg)

Reviews

There are no reviews yet.