Product information

Reviews

Shipping & returns

Product information

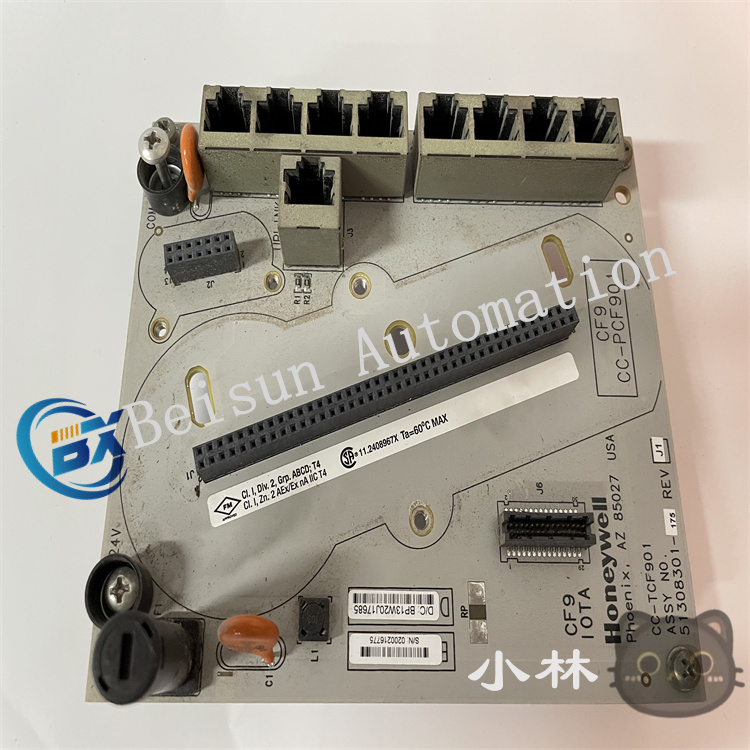

TRICONEX IMFF4703X Industrial Control Module

Features

High Reliability and Safety: It adopts a Triple Modular Redundancy (TMR) architecture, which consists of three identical branches. Each branch can independently execute control programs and work in parallel with the other two. Through software and hardware mechanisms, it performs “two-out-of-three voting” on I/O, ensuring high availability and fault tolerance in process control, and can be used in industrial environments with high safety requirements.

High Reliability and Safety: It adopts a Triple Modular Redundancy (TMR) architecture, which consists of three identical branches. Each branch can independently execute control programs and work in parallel with the other two. Through software and hardware mechanisms, it performs “two-out-of-three voting” on I/O, ensuring high availability and fault tolerance in process control, and can be used in industrial environments with high safety requirements.

Powerful Input/Output Functions: It integrates rich input/output functions for receiving on-site sensor signals or sending control commands to actuators. The “4703X” model points to specific I/O configurations or technical characteristics.

Support for Multiple Communication Protocols: It supports various industrial communication protocols such as Modbus and Ethernet/IP, facilitating integration with upper computer systems, PLCs, or DCS, and enabling data transmission and interaction.

Easy Configuration and Maintenance: It is equipped with user-friendly configuration software, allowing engineers to quickly set parameters. Meanwhile, the module provides diagnostic tools, which can simplify maintenance and troubleshooting.

Adaptability to Harsh Environments: It is designed to be resistant to high temperatures, dust, vibration, and electromagnetic interference, and can operate stably in harsh industrial environments, ensuring the continuity and stability of industrial production processes.

Application Fields

Petrochemical Industry: In scenarios such as refineries and petrochemical plants, it is used in Safety Instrumented Systems (SIS), Fire and Gas System Protection (F&G), High Integrity Pressure Protection Systems (HIPPS), etc. It can monitor and protect the production process in real-time, and take timely measures in case of abnormal situations to avoid accidents.

Petrochemical Industry: In scenarios such as refineries and petrochemical plants, it is used in Safety Instrumented Systems (SIS), Fire and Gas System Protection (F&G), High Integrity Pressure Protection Systems (HIPPS), etc. It can monitor and protect the production process in real-time, and take timely measures in case of abnormal situations to avoid accidents.

Power Industry: It can be applied in power plants, substations, etc., for monitoring and controlling various equipment and parameters in the process of power generation and transmission, ensuring the safe and stable operation of the power system.

Rail Transit Industry: It is used in signal control and vehicle control of rail transit, ensuring the safe operation and efficient scheduling of trains.

Nuclear Power Industry: In nuclear power plants, it plays an important role in monitoring and controlling nuclear reactors, ensuring the safe operation of nuclear power plants and preventing nuclear accidents.

Precautions for Use

Installation and Wiring: It must be installed and wired correctly in accordance with Triconex’s official guidelines, especially for I/O modules. Incorrect wiring may lead to system failures or safety risks.

Installation and Wiring: It must be installed and wired correctly in accordance with Triconex’s official guidelines, especially for I/O modules. Incorrect wiring may lead to system failures or safety risks.

Environmental Conditions: It is necessary to confirm that the working environment (temperature, humidity, dust level, etc.) meets the operating range of the module to prevent premature aging or failure of the module.

Software Compatibility: Before using any configuration or monitoring software, it is necessary to confirm that its version is compatible with the firmware of the IMFF4703X module to avoid communication problems or functional limitations.

Regular Maintenance: A regular maintenance plan should be formulated and implemented, including firmware updates, module cleaning, and functional testing, to ensure the long-term stable operation of the module.

Safe Operation: During operation and maintenance, all safety regulations must be observed, especially when dealing with high-risk industrial control systems, to ensure personal safety and system safety.

Reviews

Be the first to review “TRICONEX IMFF4703X Industrial Control Module” Cancel reply

Shipping & returns

Free and fast shipping

Cras condimentum sapien eu congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

Easy returns

Aliquam dapibus placerat dui, ac ullamcorper odio dapibus eget. Sed aliquam leo pellentesque est blandit, sit amet posuere dui maximus.

Order tracking

Nullam lacinia iaculis erat ut fermentum. Praesent volutpat sagittis dictum. Mauris quis egestas dui, eu iaculis turpis.

24/7 customer support

Congue tincidunt. Ut lobortis augue non justo interdum, ut vehicula massa vehicula. Aenean ut lectus augue.

.jpg)

Reviews

There are no reviews yet.