Product information

Reviews

Shipping & returns

Product information

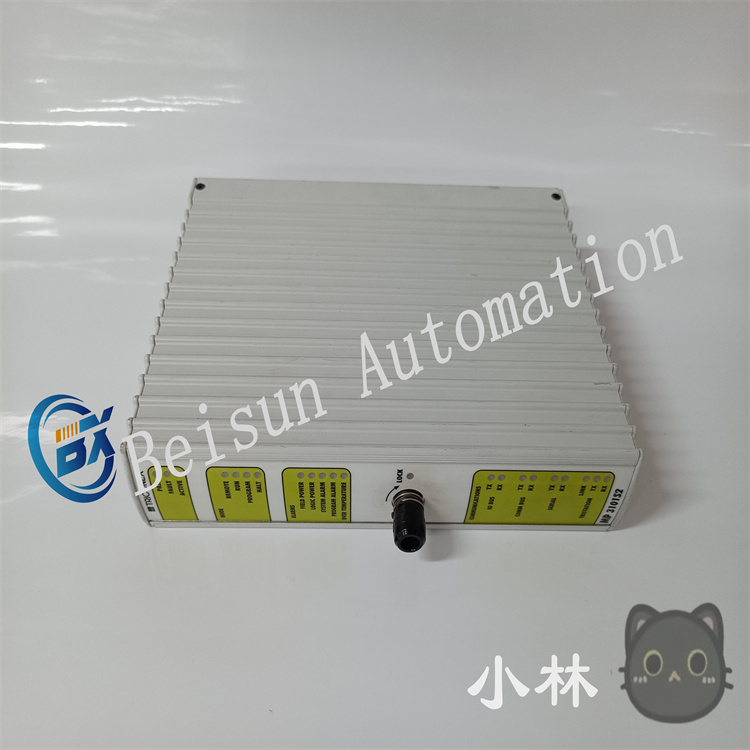

ABB PP865A 3BSE042236R2 Industrial human-machine interface products

Hardware specification

Display screen: Usually equipped with large size high-resolution TFT-LCD display, such as 19-inch screen, resolution up to 1280×1024 pixels. Such a screen can clearly display complex industrial process pictures, detailed equipment status information and a variety of graphical operation interfaces, providing operators with a good visual experience, so that they can accurately read and understand the relevant data.

Interface: Provides a variety of communication interfaces, including Ethernet interface, RS-232 interface, RS-485 interface, USB interface, etc. Rich interface types support a variety of industrial communication protocols, such as Profibus, Modbus TCP, OPC, etc., making PP865A can easily connect and communicate with various PLCS, DCS systems, drives and other industrial automation equipment to achieve seamless integration and data sharing of the system.

Functional characteristics

Powerful processing power: Built-in high-performance processor and sufficient memory, can quickly process a large number of industrial process data, real-time update equipment status, operating parameters and other information. For example, it can process data from multiple sensors in a short period of time and accurately display it on the screen, providing timely and accurate decision-making basis for operators to ensure efficient monitoring and control of industrial processes.

Flexible configuration function: Through special configuration software, users can customize personalized human-machine interaction interface according to actual application requirements. You can freely design the interface layout, add various graphic elements, define operation logic and animation effects. For example, users can design monitoring screens with different operating interfaces and control logic according to different process flows to meet the special control requirements in different industrial scenarios.

Data recording and analysis: It has the function of data recording and storage, which can record the operation history, operation log, alarm information and process data of the equipment. The data can be stored locally through the built-in storage media or uploaded to a remote server for long-term storage. At the same time, it also supports data query, analysis and export functions, which is convenient for users to diagnose faults, evaluate performance and optimize production. For example, you can query historical data to analyze the device running trend and discover potential faults in advance.

Security management: Supports the user rights management function. You can set different operation rights based on different user roles to ensure that only authorized personnel can perform critical operations, improving system security and stability. For example, you can set administrator rights and operator rights so that users with different rights can only perform operations corresponding to their rights to prevent damage to the system caused by misoperations or illegal operations. In addition, there are some security protection mechanisms, such as data encryption, anti-virus functions, etc., to protect the information security of industrial control systems.

.jpg)

Reviews

There are no reviews yet.